Polishing Drum Magnet (PDM) Model

European Patent: EP 20135149 B1

US Patent: US20090159511 A1

Advanced copper cleaning for ferrous scrap processing

The SGM Polishing Drum Magnet (PDM) is a specialized electromagnetic drum separator, engineered to reduce copper content in ferrous shred by efficiently removing electrical rotors with copper windings (“meatballs”). This patented technology enables scrap processors to significantly decrease manual sorting (pickers), improving overall efficiency and metal purity.

How the SGM’s PDM works

The SGM PDM Model is an enhanced version of the Mega Drum Magnet, featuring a custom anodized aluminum strip winding that allows for precise direct current control, ensuring maximum accuracy in separating electrical rotors from ferrous scrap.

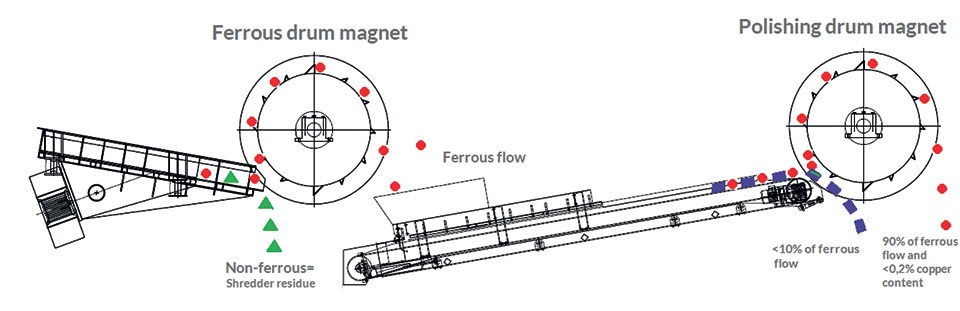

- Initial material flow: Mixed ferrous scrap containing meatballs (copper-wound electrical rotors) enters the system.

- Magnetic separation: The PDM divides the ferrous flow into two distinct streams:

- Short drop flow: Concentrates meatballs and a minor amount of ferrous.

- Positive flow: Retains most of the ferrous while minimizing copper contamination.

- Copper reduction efficiency: Typical copper content in ferrous shred (~0.3%) is reduced to below 0.2%, ensuring higher-quality ferrous output.

Key features & benefits

- Layer windings generate stronger magneto-motive force, improving metal separation.

- Reduces copper contamination in ferrous scrap from 0.3% to <0.2%.

- Segregates ferrous scrap into two distinct flows, optimizing downstream processing.

- Constructed with a single machined billet shaft (no welding) for maximum strength.

- Features an outer replaceable layer for extended wear resistance.

- Allows precise orientation of magnet polarities for optimized performance.

Customizable features

- Conveyor belt feeding system – Ensures optimal material distribution into the PDM.

- Electronic control panel – Allows precise current management for consistent magnetic separation.

- Drum sprocket & drive assembly – Available upon request for customized configurations.

Scrap with an iron content of less than 10% together with most rotors is discarded at a collection point (short flow). Materials composed of 10% to 90% iron and a minimum number of rotors, are attracted and held by the drum until released at a different collection point (positive flow).

In the process of selecting the PDM magnetic separator for copper cleaning, the percentage of this metal in the material collected in the positive flow drops from 0.3% to 0.2%.

The precision in the selection of the rotors is also due to the coating of the magnet with an anodized aluminum tape that allows you to set the desired continuous current flow.

The strength of the PDM model is guaranteed by the precise dimensions of all its mechanical components that allow a perfect gear between them.

The main shaft consists of a single seamless block.

The outer shell is made of a double layer of manganese steel, in which the outer layer can be replaced in the event of wear.

The magnet is also equipped with a counterweight so that it can be directed according to the applications.

PDM models

SGM Magnetics produces 10 different models based on:

- Size

- Diameter of magnets and side flanges

- Magnet weight

- Magnet power

- Rotational speed

- Maximum working distance between drums and material to be selected

- Number of gills on the body

- Engine force required

Processed Material