European patent: EP2908955 A1

US patent: 9.475.063 US B2

Maximizing Efficiency, Minimizing Contaminants

Heavy Melting Scrap (HMS) typically contains between 6-12% contaminants,including dirt, inert materials, and non-ferrous metals. These impurities negatively impact steel production by: Reducing furnace yield; Increasing electricity consumption per ton of steel produced; Generating higher slag volumes; Raising lime consumption to maintain slag basicity.

SGM Magnetics’ Scrap Cleaning Line (SCL) for HMS is a high-efficiency solution designed to refine scrap by reducing contaminants, optimizing furnace performance, and improving overall steel quality.

It can be sized for processing 100 and 150 tons per hour which is ideal for steel mills using 300.000 tons per year of scrap to their furnace.

How It Works

Our Scrap Cleaning Line efficiently separates contaminants through a series of advanced processes:

- Charging Hopper – Feeds the HMS into the system

- Vibrating Feeder + De-dusting Screen – Removes loose dirt and fine contaminants before magnetic separation

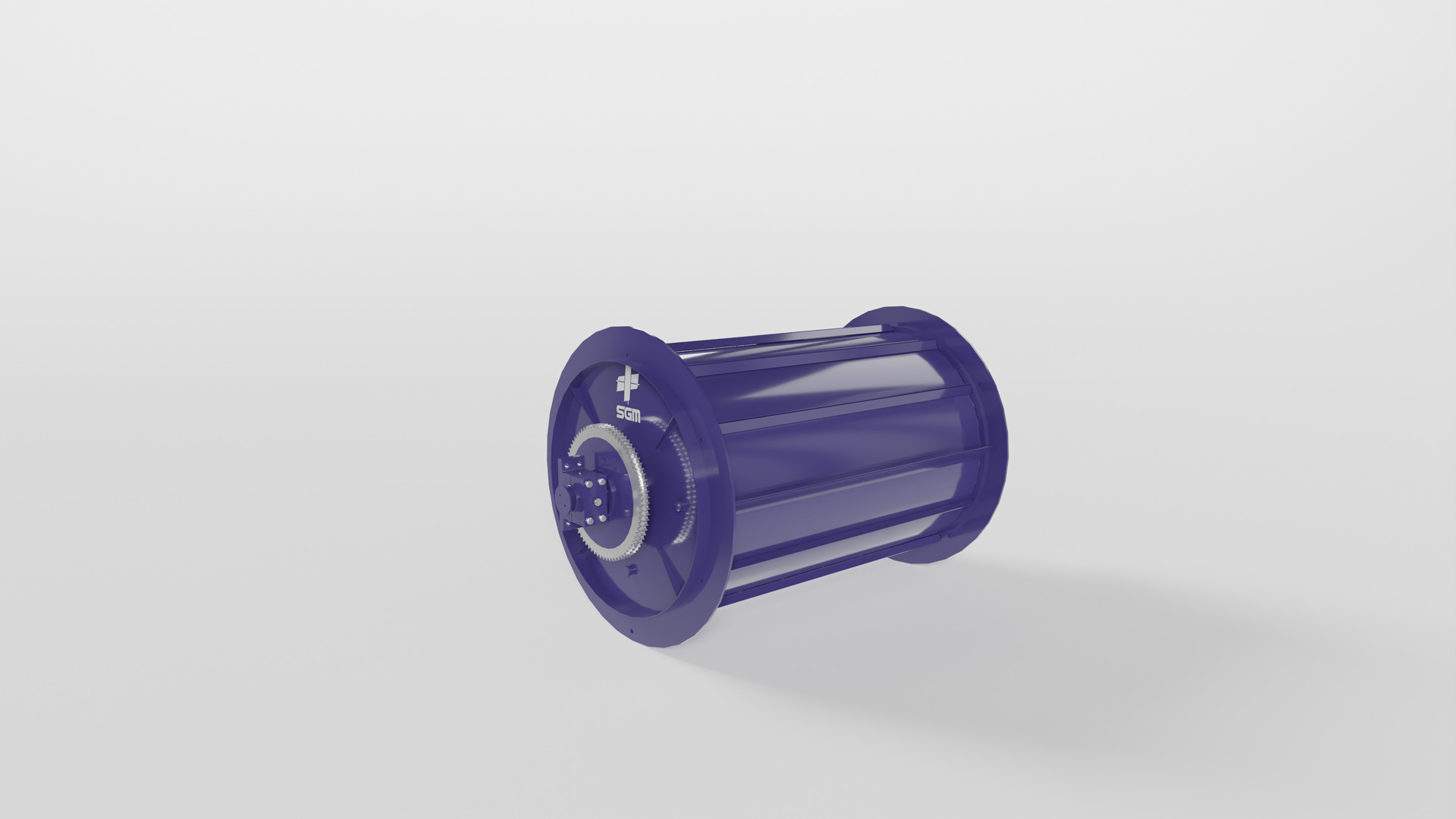

- Drum Magnet with Proprietary Radial Polarities – Ensures optimal separation of ferrous materials from non-ferrous impurities

- Ferrous Belt Magnet – Captures and cleans the final ferrous output

With SGM’s proprietary electro-drum magnet, the system ensures maximum separation efficiency. A patented drum with a powerful magnet with radial polarity is used to clean HMS scrap, allowing for a greater distance between the conveyor belt and the drum itself.

The non-ferrous removed from the HMS can be sold to metal recyclers for their typical valuable non-ferrous metal content.

Technical Highlights

- Designed for maximum robustness and heavy duty.

- Charging hopper.

- Vibrating feeder completed with de-dusting screen.

- Extremely strong proprietary electro-drum m ance between the feeder end and drum surface, consequently maximizing the liberation of contaminants.

- Can be supplied as a complete solution or in modular parts.

Engineered for Heavy-Duty Performance

SGM’s Scrap Cleaning Line is designed for maximum robustness and continuous operation in demanding environments.

Available Capacities:

- SCL-50: 50 tons per hour

- SCL-100: 100 tons per hour

- SCL-150: 150 tons per hour

Key Benefits of the SGM Scrap Cleaning Line

✅ Higher Furnace Yield – More efficient scrap usage, increase in steel production

✅ Energy Savings – Reduced power consumption per ton of steel

✅ Lower Slag Production – Minimizes waste and the need for additional lime

✅ Environmental Impact – Decreases CO₂ emissions, dust levels, and overall pollution

✅ Revenue from Separated Materials – Extracted non-ferrous metals can be sold to recyclers

✅ Rapid Return on Investment

Global Leadership in Scrap Refining

Our Scrap Cleaning Lines are installed worldwide, including in major steel-producing markets like Turkey, the largest importer of HMS.