High-performance magnetic separation for heavy-duty industrial applications

The SGM Electro Drum Magnet (TMR Model) is a high-efficiency ferrous separator designed to deliver maximum magnetic attraction for auto shredder scrap and other industrial applications. Featuring an anodized aluminum strip winding for superior heat dissipation and low electrical density to reduce heat build-up, the TMR Model ensures optimal ferrous recovery with continuous operation in demanding environments.

Key features & benefits

- Designed with axial polarities and an enlarged winding, increasing magnetic energy and depth of attraction.

- Built with heavy-duty steel and a single-piece machined billet shaft (no welds) for maximum reliability.

- Includes an inner 10 mm manganese steel shell and an outer 8 mm shell for wear resistance.

- Can be mounted above or below a conveyor belt or shaker pan, allowing for versatile material handling.

- Ferrous materials are attracted from over 100 cm (3 ft) away, ensuring efficient separation and minimal losses.

- Equipped with two 115 mm (4 ½”) paddles and 8 to 10 knock-off bars, improving metal discharge efficiency.

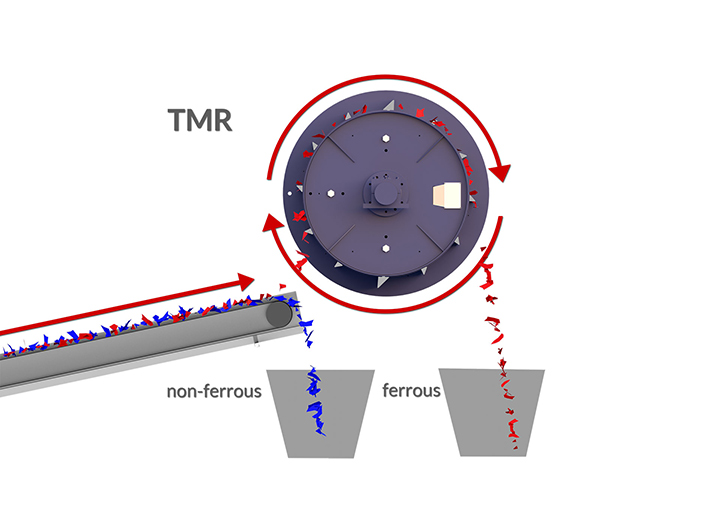

How the TMR model works

- Material enters the system via a belt, shaker pan, or direct drop.

- Ferrous metals are magnetically attracted and held onto the drum surface.

- Non-ferrous materials continue their natural trajectory, ensuring clean separation.

- Knock-Off Bars facilitate discharge, directing recovered metals into a dedicated collection area.

The TMR can be installed above a conveyor, allowing ferrous materials to be pulled from a distance, or beneath a feeder, where materials are dropped onto the drum for separation.

TMR models

SGM Magnetics produces 9 models of TMR drum electromagnetic separators, each with different:

- Weight

- Magnet power

- Maximum working distance between drum and shredded car residues

- Current demand

- Speed of rotation of the drum

- Number and size of gills on the body

- Typical applications

- Magnetic drums are used for the recovery or elimination of ferrous metals in many

Customizable features

- Additional manganese steel shell – Outer layer (8 mm) can be added for extended durability.

- Counterweight system – Facilitates precise alignment of magnetic polarities.

- Drum sprocket & Drive assembly – Available upon request for customized installations.

Why choose the SGM TMR Model?

- Optimized for industrial use – Designed for continuous operation in high-volume environments.

- Higher magnetic field strength – Ensures deeper attraction and improved ferrous recovery.

- Flexible installation – Can be mounted above or below conveyors, adapting to different processing needs.

- Proven performance – Successfully used in scrap recycling, waste processing, and heavy-duty applications worldwide.