Aluminum recycling is a key pillar of sustainability, significantly reducing energy consumption and greenhouse gas emissions. Producing secondary aluminum from recycled materials requires only 5% of the energy needed for primary production, generating just 0.6 kg of CO₂ per kilogram of recycled aluminum. This process saves over 100 million tons of CO₂ annually, reinforcing aluminum’s role in a circular economy. Remarkably, about 75% of all aluminum ever produced is still in use today, highlighting its endless recyclability and long-term value. Despite its high recyclability, recycling rates vary, with an average of 35% and a target of 50% by 2050. The main challenges include:

- Diversity of alloys: automotive applications use multiple aluminum alloy series (2XXX, 5XXX, 6XXX, and 7XXX), making sorting complex.

- Post-consumer scrap contamination: the presence of mixed metals, coatings, and impurities affects purity and process efficiency.

- Scarcity of high-quality scrap: the demand for clean, high-purity aluminum continues to rise, putting pressure on recyclers to recover more efficiently.

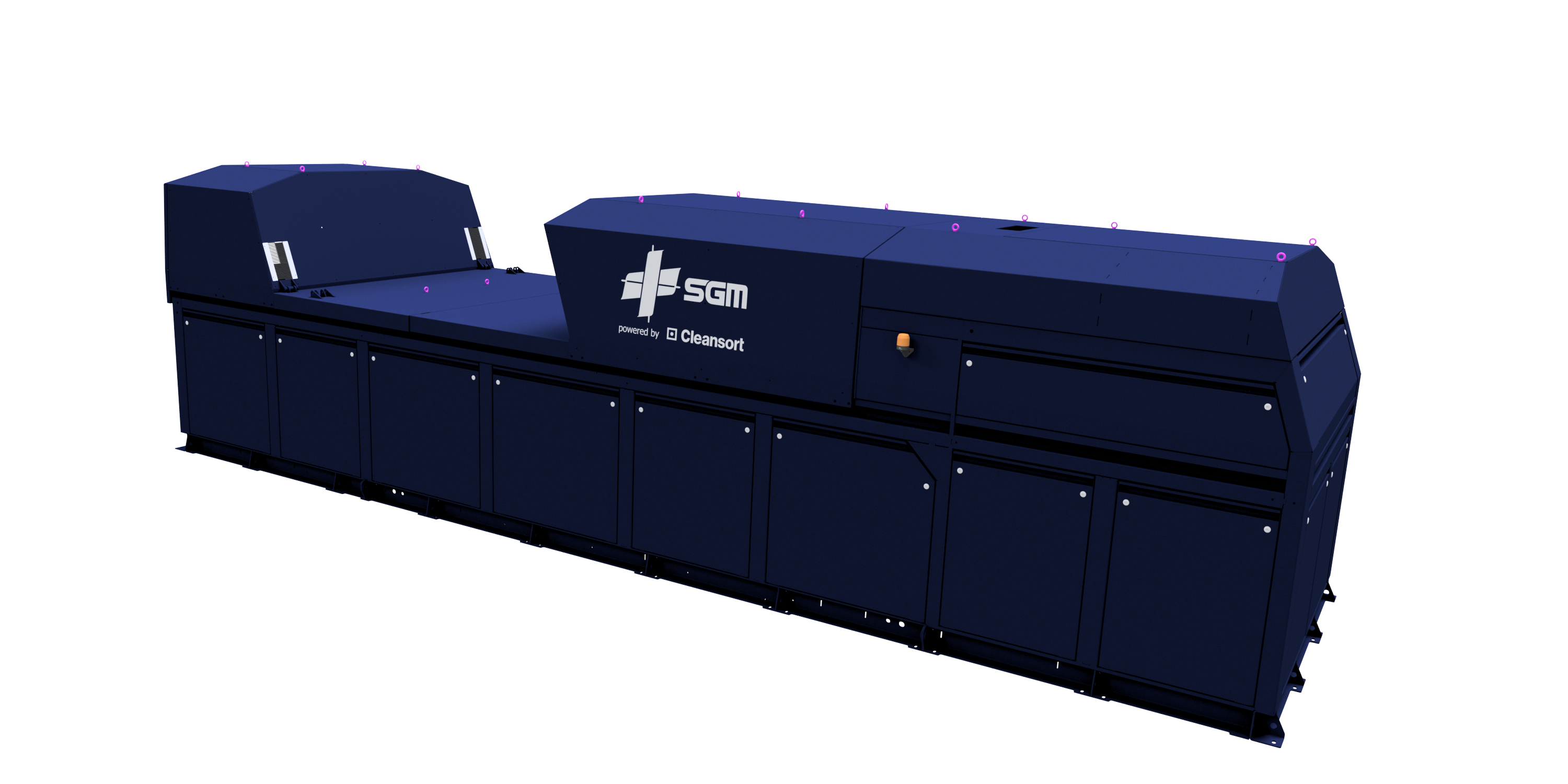

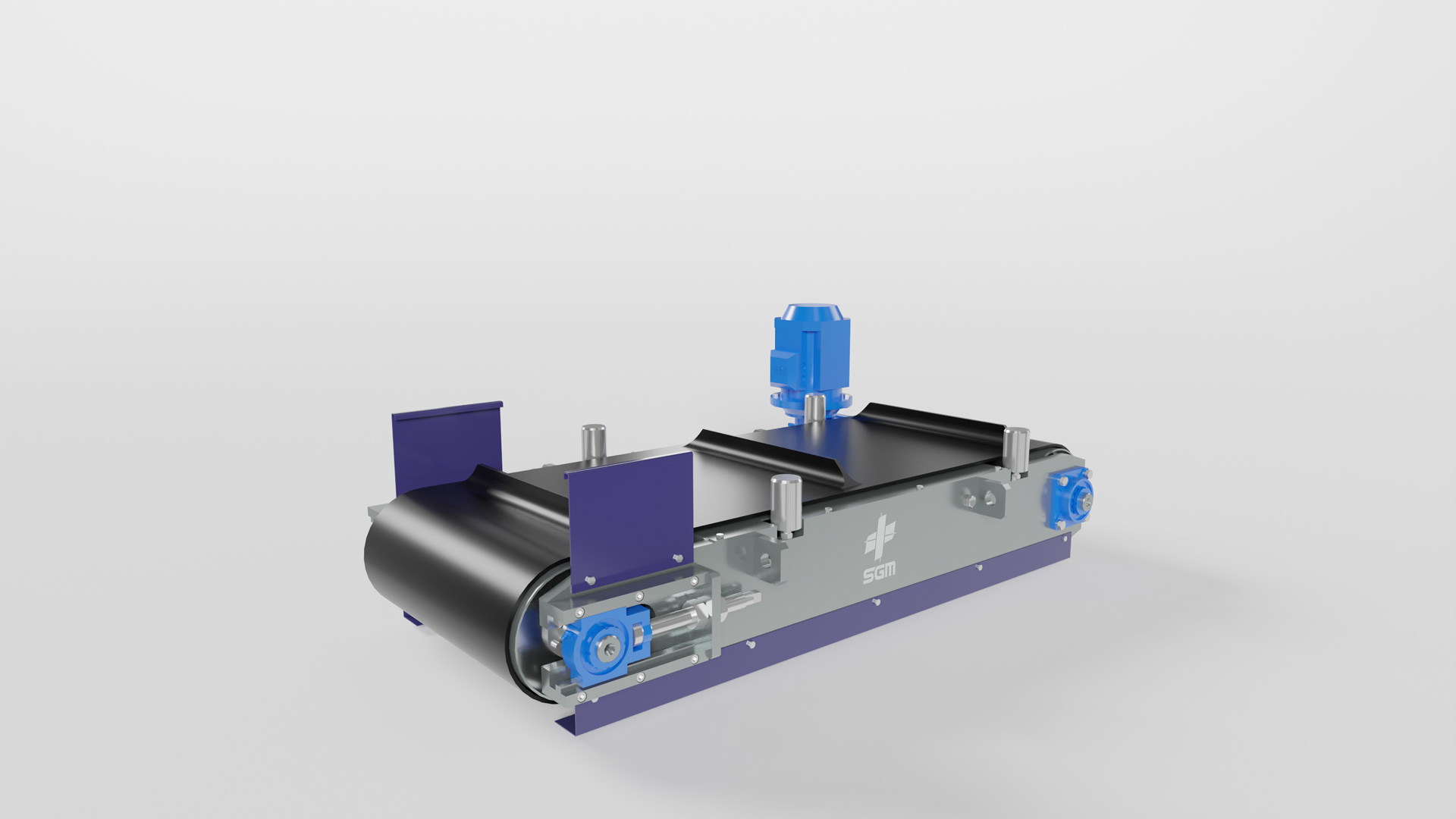

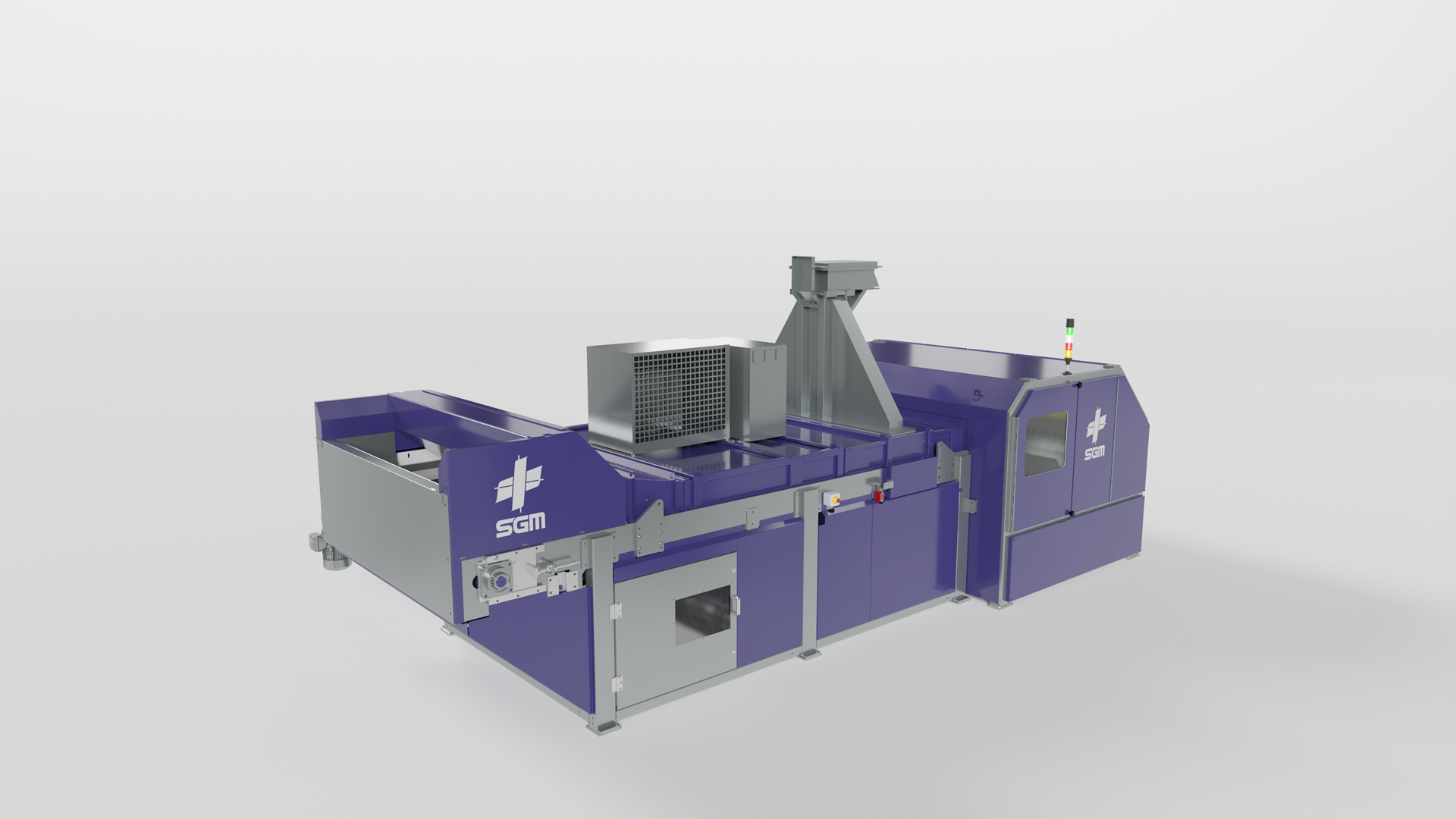

SGM’s advanced sorting technologies for aluminum recycling

SGM has developed a comprehensive range of separation technologies, designed in collaboration with aluminum smelters to meet industry standards. Our solutions maximize recovery rates, purity, and operational efficiency. The result is a main stream of scrap aluminum with Zn, Cu, Mg and Fe reduced by a multiple of times. With aluminum profile scrap, Zn can pass from the typical 0,16-0,25% down to 0,03-0,05%. With taint tabor, Zinc can pass from the typical 0,5% down to 0,10-0,15% and in the case of tense, can pass from the typical 5-6% down to 1-2%.

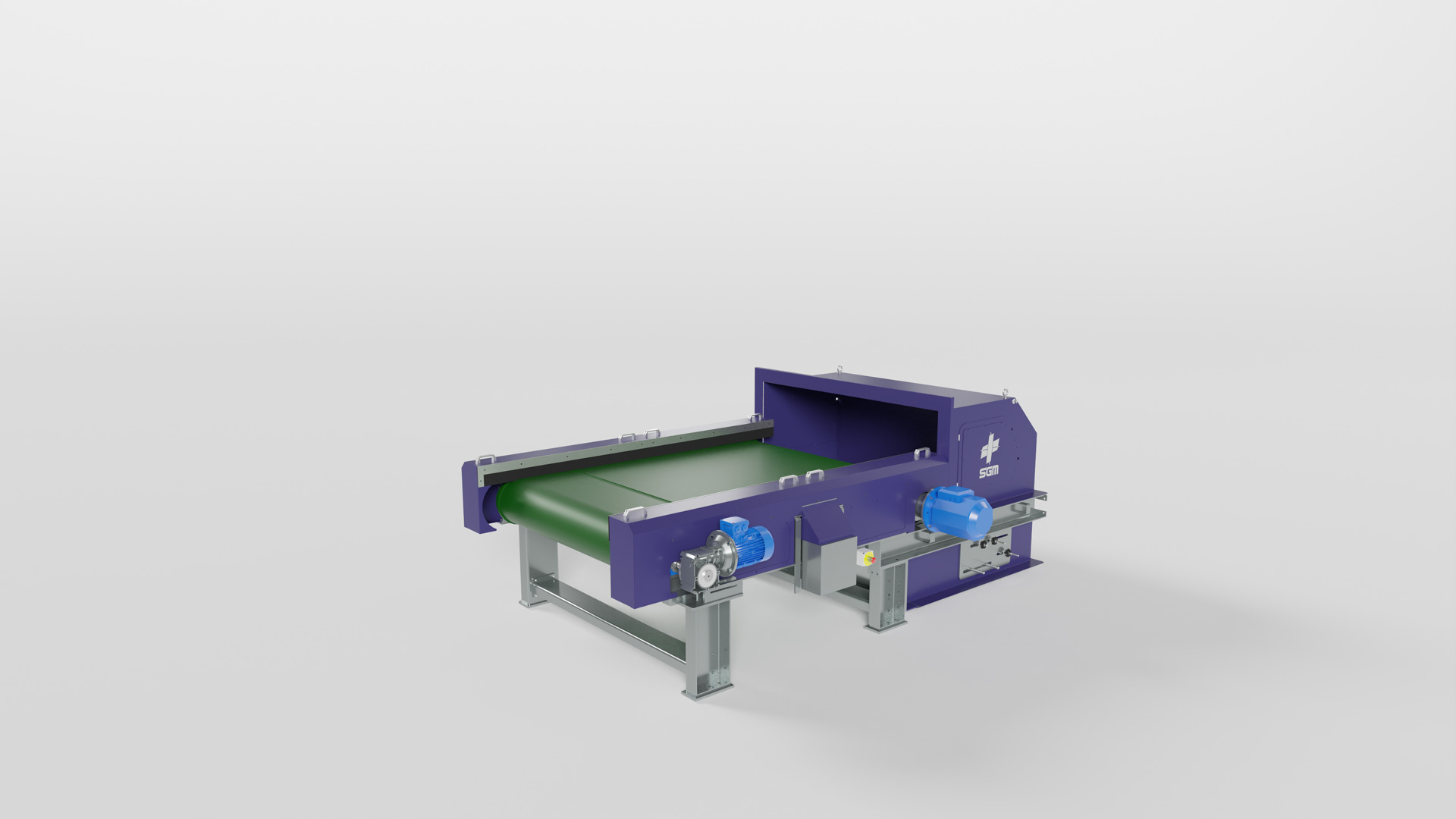

SGM provides a comprehensive range of sorting technologies to optimize aluminum recycling

XRT (X-Ray Transmission): This technology sorts aluminum based on atomic density, making it ideal for:

- Separating light metals from heavy non-ferrous metals.

- Distinguishing light aluminum alloys (1XXX, 5XXX, 6XXX) from heavier alloys (2XXX, 3XXX, 4XXX, 7XXX).

- XRT technology provides high-volume processing and proven reliability in industrial applications.

XRF-T (X-Ray Fluorescence & Transmission): This combined technology provides density and chemical composition analysis to refine aluminum sorting further. It is particularly useful for:

- Recovering thick pieces of light aluminum from previously sorted fractions.

- Sorting low- and high-density alloyed aluminum fractions.

XRF-T technology integrates X-ray transmission and fluorescence, allowing recyclers to recover aluminum that would otherwise be discarded, increasing overall recycling rates and minimizing material losses. -

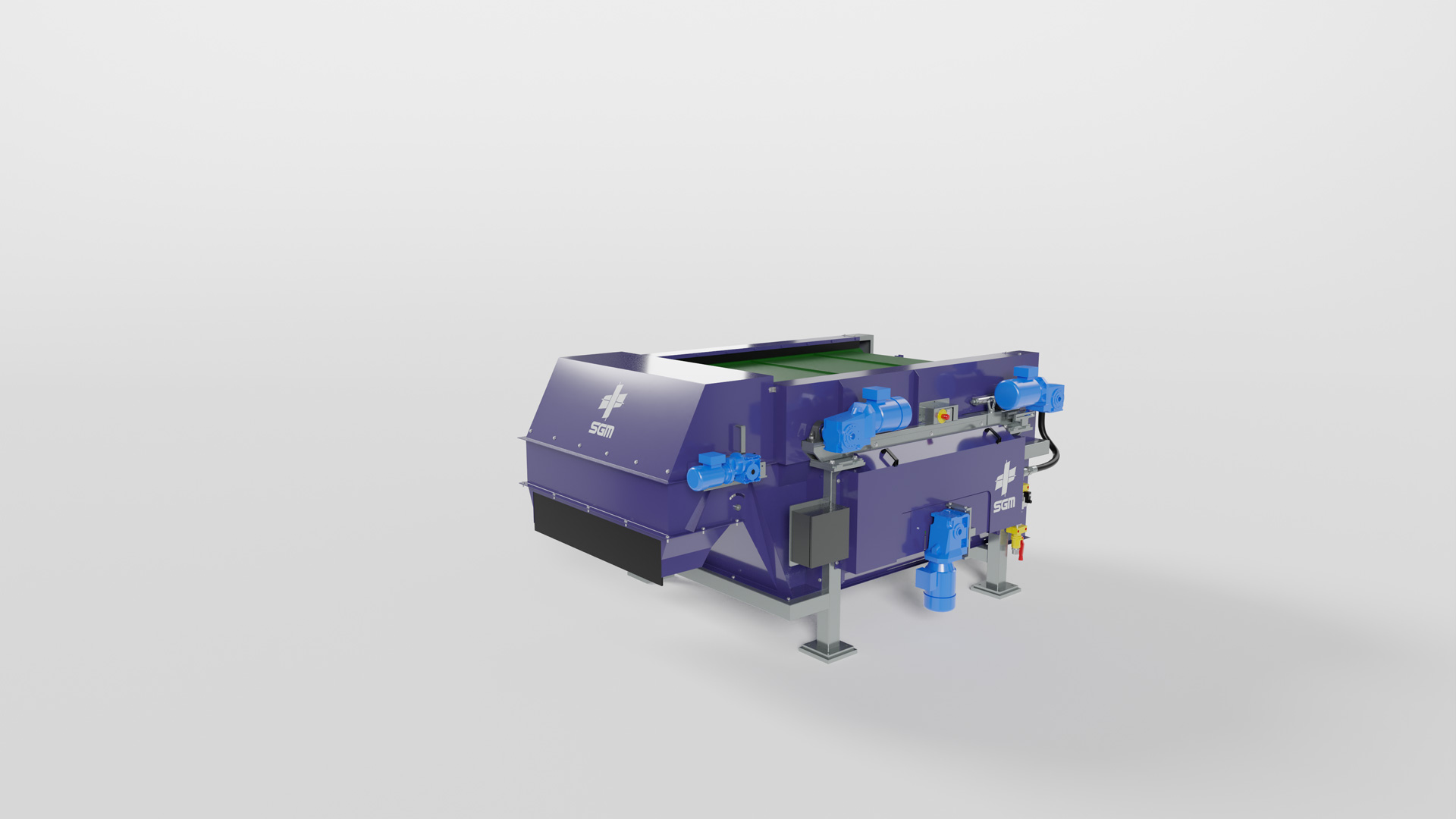

LIBS (Laser-Induced Breakdown Spectroscopy): This technology identifies aluminum’s chemical composition, enabling the precise sorting of:

- Specific aluminum alloys, such as 6060, 6061, and 6082.

LIBS technology provides an ultra-precise sorting process that can distinguish elements like magnesium, silicon, copper, and zinc.

With multiple references at aluminum smelters worldwide, including in Italy, Spain, Germany, the UK, the USA, South Korea, China, India and Japan, SGM brings extensive expertise to its customers, ensuring optimized aluminum recovery and processing.

SGM offers customized solutions tailored to meet specific customer needs and preferences, whether through complete turn-key systems or as a supplier of key separation technologies. This flexibility allows smelters to integrate high-performance sorting solutions seamlessly into their operations, maximizing efficiency, purity, and profitability.

Customers that trust us