Technical Specifications

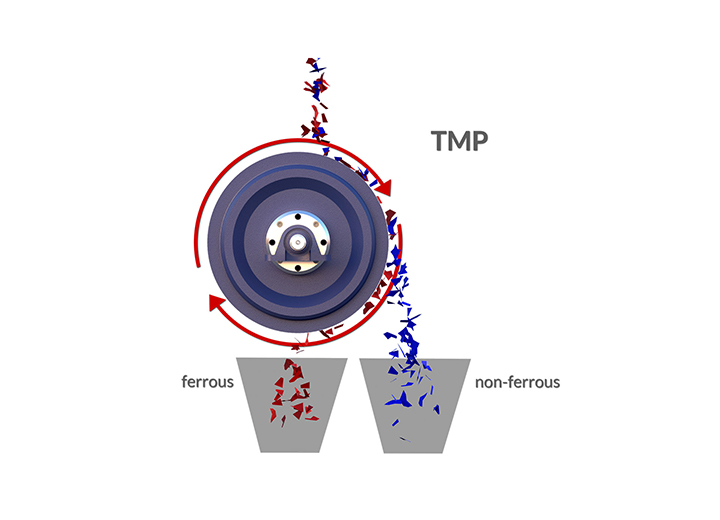

Drum magnets are mainly made of two parts, an inner fixed part consisting of the permanent magnet itself. Which is active on about 200° of the circumference of the drum. As well as an outer part consisting in a rotating shell provided with knock-off bars. Permanent drum magnets can feature a very strong attraction on their surface, possibly even stronger than electromagnetic drums, but the use of permanent magnets limits the depth of their attraction. For this reason, it is recommended to feed the drum magnet from above with material falling onto the drum. The ferrous is held on by the magnet and discharged separately from the natural trajectory of the non-ferrous stream. The SGM Permanent Drum Magnets TMP Model is used in many industries (car shredder, slag, foundries, domestic waste, wood waste, WEEE, etc) for many heavy duty applications and are designed in many different sizes. Feeders can be belts, shaker pans or chutes.

Operation

Drum sprocket and drive assembly can be supplied upon request. The SGM TMP magnets feature a unique proprietary magnetic circuit design which magnifies their magnetic gradient and attraction even on lightly magnetic materials. This proprietary magnetic circuit consists in a combination of Neodymium and Ferrite permanent magnet blocks, where the Neodymium permanent magnets contribute to the strong attraction (gradient) while the Ferrite magnets still guarantee a deep attraction. Some small diameter TMP magnets used for fine material, for which a deep attraction is not necessary, are only provided with Neodymium permanent magnets. For the best choice of your Permanent Drum Magnet Separator, please contact SGM for recommendations.