Steel Plates

Choosing the Right Magnetic Lifting Solution

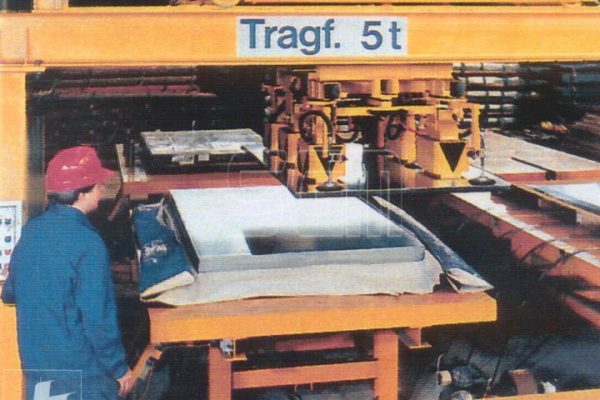

Electromagnets (EM) for Steel Plates

SGM EM solutions are designed for lifting single or multiple plates, offering variable magnetic force for precise and controlled handling. They are particularly suited for automated handling systems, where plates need to be measured, stacked, and released with precision.

- Automatic Plate Detection – Constant current control ensures accurate measurement of lifted plates, optimizing loading operations.

- Efficient Multi-Plate Lifting – Ideal for applications requiring batch lifting of plates in production lines and warehouses.

- High-Capacity Lifting – Designed to handle large steel plates up to 5000 mm (197 inches) wide and 24 meters (79 feet) long.

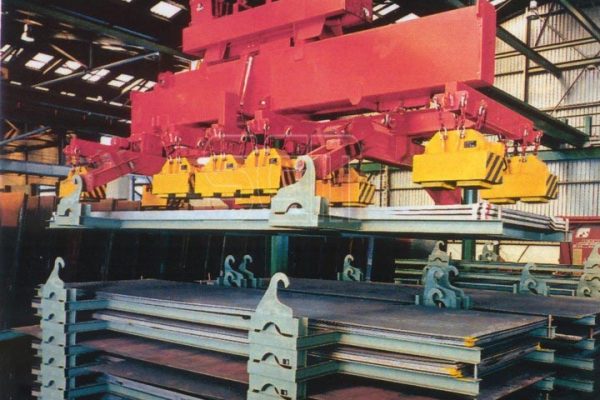

Electro Permanent Magnets (EPR) for Steel Plates

SGM EPR solutions are designed for single plate lifting or handling small stacks of thin plates. Unlike electromagnets, EPR magnets retain their lifting force even in case of power loss, offering an additional layer of safety.

- Fail-Safe Operation – Lifting force is independent of external power sources, preventing accidental load drops.

- 100% Duty Cycle – No heat generation allows for continuous 24/7 operation, making it ideal for high-frequency handling.

- Custom Configurations – Tailored solutions for plates of various dimensions, ensuring flexibility for different industrial needs.

Why Use SGM Lifting Magnets for Plate Handling?

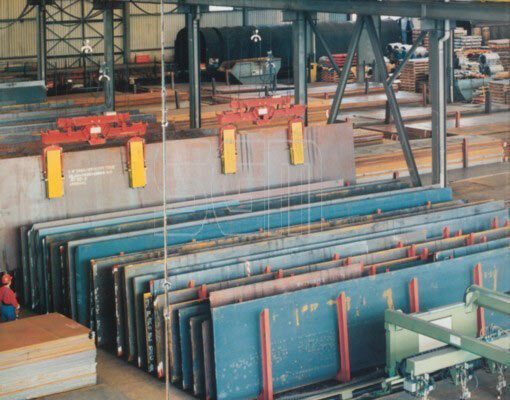

1. Increased Safety & Load Control

Magnetic lifting eliminates the risks associated with chains, slings, and clamps, reducing the need for manual handling. A single operator can manage the entire lifting process remotely from the crane cabin or via wireless control, keeping personnel at a safe distance.

SGM magnet control systems provide partial and variable magnet force, allowing precise selection of plate quantities. Once the picking operation is complete, the system automatically switches to full magnetic force for safe and secure transportation.

2. Damage-Free Handling

Traditional lifting methods often cause dents and scratches due to mechanical clamps or chains. SGM magnets grip the plate’s surface uniformly, preventing deformations and ensuring damage-free handling.

3. Optimized Storage & Space Utilization

Magnetic lifting eliminates the need for wooden spacers between stacked plates, allowing for denser storage and better warehouse utilization. Unlike forklifts or manual lifting methods, magnets do not require extra space between stacks, maximizing available storage capacity.

4. Increased Productivity

- Faster handling cycles – Lifting and releasing operations take seconds, significantly reducing material handling time.

- Selective plate pickup – The partial magnet energizing function allows the operator to lift only the required number of plates, even with thin gauges.

- Precise stacking – The feathering option in the magnet control system enables partial release of plates onto different stacks, improving organization and workflow efficiency.

5. Absolute Safety with Electro Permanent Magnets (EPR)

- No risk of load drops due to power failure or cable interruption.

- 100% duty cycle, EPR magnets do not overheat, making them ideal for continuous 24/7 operations.

- Flux Measuring Device (FMD) integration – Ensures constant monitoring of the magnetic force for maximum safety.

Custom Lifting Solutions for Every Application

SGM designs tailored lifting magnet systems to meet the specific needs of each customer.

Designed and manufactured in compliance with European Standard EN 13155, SGM lifting magnets provide maximum safety, efficiency, and precision in plate handling.