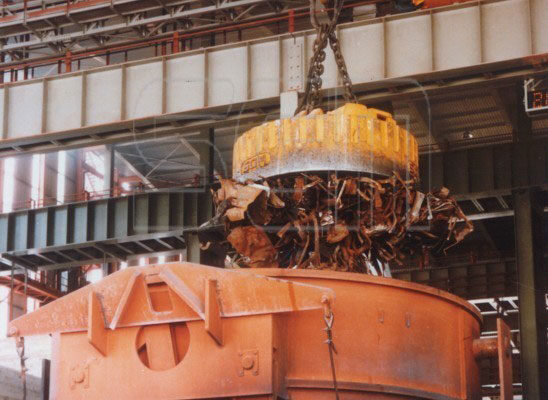

Scrap

Scrap metal includes a wide variety of ferrous materials, ranging from industrial steel production residues to metallic waste from demolition sites. This can include structural beams, pipelines, machinery parts, vehicle frames, and reinforcing bars (rebar), all of which must be efficiently handled for recycling and reuse in steel production.

Handling scrap presents several challenges due to its irregular shapes, varying densities, and potential contamination from coatings, rust, or residual concrete in demolition scrap. Additionally, large and heavy metal pieces require powerful lifting systems that can ensure safe and efficient loading, transport, and processing. An optimized scrap handling solution minimizes material loss, increases processing speed, and improves overall safety in scrapyards, steel mills, and recycling plants.

SGM Magnetics Solutions for Scrap Handling

SGM Magnetics designs and manufactures high-performance lifting magnets specifically engineered for scrap yard operations, steel mills, and metal recycling plants. Our product range includes circular scrap magnets and mega octagonal scrap magnets, offering maximum durability, lifting efficiency, and operational reliability.

Circular Scrap Magnets

Circular electromagnets are the standard solution for lifting scrap metal in high-volume operations. Designed for heavy-duty use, they offer strong magnetic fields and high heat resistance, ensuring consistent lifting performance under demanding conditions.

To enhance heat dissipation and extend magnet lifespan, SGM utilizes anodized aluminum strip windings as standard, which provide superior electrical insulation and durability, even in high-temperature environments.

Mega Scrap Magnet – Optimized for Consteel® Operations

The SGM Mega Scrap Magnet is an innovative alternative to circular scrap magnets, specifically designed for loading scrap onto conveyor belts in continuous steelmaking processes (Consteel® technology).

- Homogeneous Scrap Distribution: Equipped with a patented double magnetic circuit, this system ensures a more even distribution of scrap over the entire magnetic surface, eliminating the common “mushroom effect” seen with traditional circular magnets.

- Consistent Feed for Consteel® Furnaces: Ensures a steady scrap flow, preventing material loss and optimizing energy savings in continuous charging processes.

- Tipping Function for Precise Scrap Dosing: An integrated electronic device briefly cuts magnet voltage, allowing operators to control the drop of scrap onto the conveyor belt, ensuring accurate material dosing.

- Heat-Resistant Design for Maximum Durability: The octagonal shape of the Mega Scrap Magnet, combined with anodized aluminum windings, provides optimal heat dissipation, preventing performance degradation and increasing the working cycle efficiency of the magnet. The chemically treated aluminum surface offers excellent insulation, maintaining electrical integrity even under extreme conditions.

Key Advantages of SGM Scrap Lifting Magnets

- Faster scrap handling reduces operational downtime and increases processing capacity.

- Eliminates manual handling risks associated with traditional lifting methods, ensuring a safer work environment.

- Advanced magnetic circuit designs minimize power usage while maintaining high lifting performance.

- Built with high-durability materials to withstand continuous-duty cycles in harsh industrial environments.

Custom Scrap Handling Solutions

SGM Magnetics provides tailored lifting solutions based on operational needs, scrap density, and furnace loading requirements. Our systems are designed in compliance with European Standard EN 13155, ensuring safety, efficiency, and long-term performance in demanding industrial applications.