Technical specifications

The SGM DNE self-cleaning electromagnetic separator is designed for applications requiring the efficient separation of ferrous materials from non-ferrous scrap, industrial, and household waste.

Its versatile design allows for the recovery of ferrous metals from materials of different origins, making it an ideal solution for various recycling and waste processing operations.

Key Features

- Optimized magnet performance – Designed to maximize the active separation zone for high-efficiency ferrous recovery.

- Robust construction – Heavy-duty carbon steel frame for durability.

- Manganese steel conveyor belt base – Facilitates the smooth discharge of attracted ferrous material.

- Corrosion-resistant finish – External surfaces are coated with Chrome-Zinc and anti-corrosion paint for extended durability.

Optional Features

- Belt speed sensor – Monitors belt revolutions for optimal operation.

- Belt stop sensor – Detects stoppages for system protection.

- Outdoor protection kit – Ensures reliable performance in harsh weather conditions.

Operation

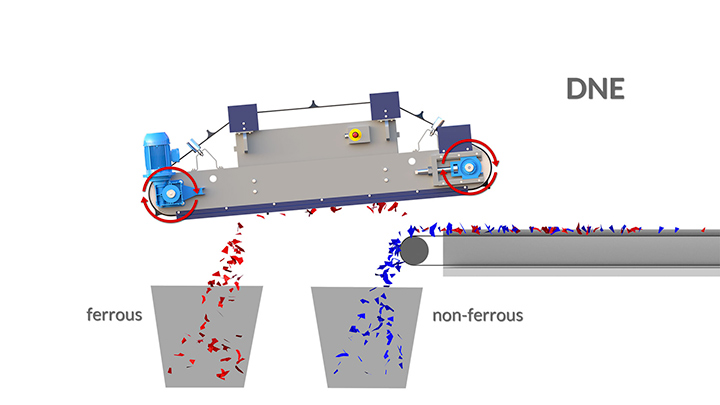

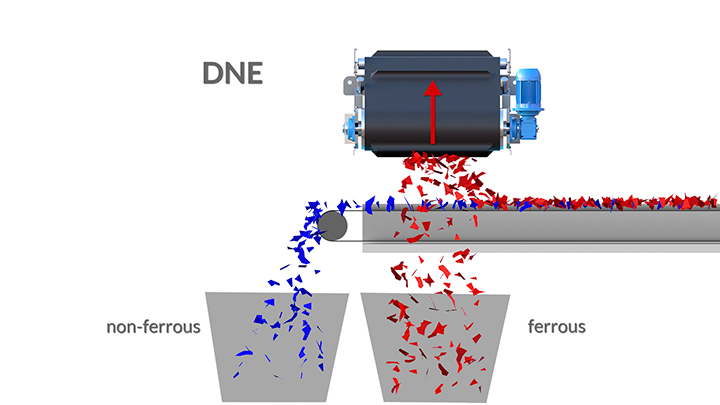

The DNE suspended electromagnet can be installed in two configurations:

- Transversely across the conveyor belt, attracting and removing ferrous materials as they pass underneath.

- At the end of the conveyor (head pulley installation), where ferrous objects are extracted just before material discharge, taking advantage of the natural separation of materials.

Once attracted by the magnetic field, ferrous particles remain attached to the belt until they reach the discharge area, where they are automatically released into a designated collection zone.

Magnetic Circuit Design

The laminated high-permeability iron magnetic circuit is engineered to generate a strong magnetic gradient, ensuring maximum separation efficiency. The field intensity is highest in the central attraction area for strong capture, while it gradually decreases towards the discharge area, allowing for easy material release.

DNE Models

SGM Magnetics offers 20 models of DNE self-cleaning electromagnets, which differ based on:

- Conveyor belt speed compatibility

- Required power input

- Magnet dimensions (length, width, height)

Processed materials