Self-Cleaning Permanent Magnetic Separator – DNP Model

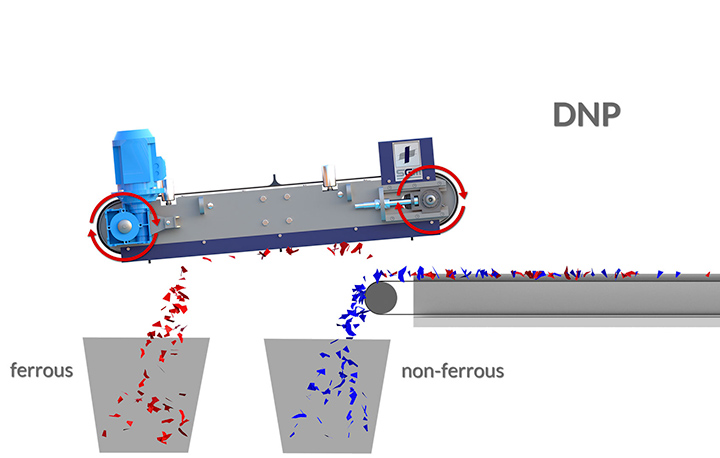

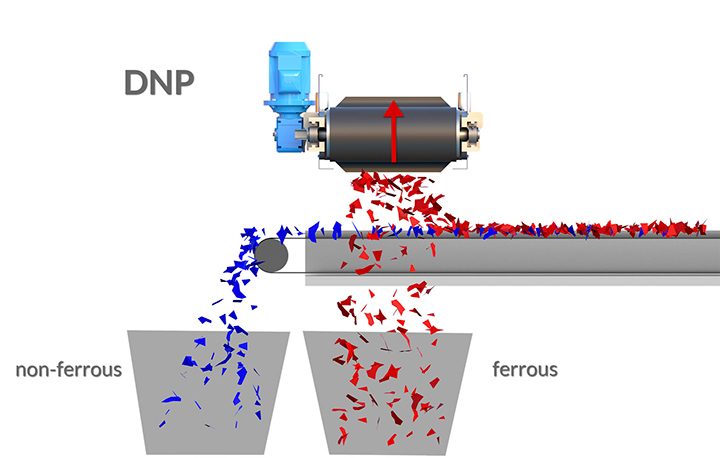

The SGM DNP Model is a self-cleaning permanent magnetic separator designed for continuous removal of ferrous contaminants from material streams. Positioned near the head pulley of a conveyor belt, this separator ensures efficient extraction of tramp iron while maintaining high operational reliability.

Technical specifications

Advanced Magnetic Circuit Technology

HG Magnetic Circuit Design → Utilizes high-energy permanent magnets with poly-directional gradient control, ensuring deep magnetic field penetration.

Semi-Closed Magnetic Circuit → Composed of permanent magnet blocks between two polarities, maximizing ferrous material adhesion for optimal separation.

Wear-Resistant Construction → Built with manganese steel housing for durability in demanding industrial environments.

Key Features

- 30 Available Models → Customizable based on conveyor speed, engine power, and dimensions to meet different application requirements.

- Heavy-Duty Belt Design → Equipped with a closed-loop anti-abrasion rubber belt featuring trapezoidal slats, applied through a high-temperature vulcanization process for enhanced durability.

- Optimized Installation Distance → Maximum recommended clearance from the material conveyor: 200-250 mm for effective separation.

Optional features

- Conveyor Belt Revolution Counter Sensor → Monitors operational speed for optimized efficiency.

- Conveyor Belt Stop Sensor → Ensures operational safety by detecting belt stoppages.

- Outdoor Protection Kit → Designed for reliable performance in harsh environmental conditions.

Efficient and Durable Design for Continuous Ferrous Separation

The SGM self-cleaning permanent magnetic separator is engineered for optimal ferrous removal, positioned near the head pulley of the conveyor belt transporting the processed material.

Optimized Installation Distance → The ideal gap between the suspended magnet and the waste/scrap conveyor is 200-250 mm, ensuring maximum separation efficiency.

High-Permeability Magnetic Structure → Magnets are embedded in an iron housing with exceptional magnetic permeability, enhancing field strength and coverage.

Wear-Resistant Construction → The entire structure is reinforced with manganese steel, providing durability in high-impact environments.

Heavy-Duty Belt System → The ring-closed, anti-abrasion rubber belt features trapezoidal-shaped rubber slats, applied using a high-temperature vulcanization process to ensure longevity and reliability in continuous operations.

Applications & Processed Materials

Recycling & Waste Processing → Municipal solid waste (MSW), incinerator bottom ash (IBA), auto shredder residue (ASR).

Mining & Quarrying → Extracting tramp iron from ores and aggregates.

Industrial & Manufacturing Facilities → Protecting processing equipment by removing unwanted ferrous materials.

DNP Models

SGM Magnetics offers 30 different models of DNP self-cleaning permanent magnets, designed to meet varied industrial requirements. Each model is optimized based on:

Conveyor Belt Speed → Ensuring precise synchronization with the material flow for maximum separation efficiency.

Engine Power Requirements → Tailored configurations to match specific power capacities and operational demands.

Magnet Dimensions → Available in multiple lengths, widths, and heights to accommodate different processing setups.

Processed Materials