SGM Magnetics offers a complete range of drum magnets designed for efficient ferrous recovery and separation in heavy-duty industrial applications. Our drum magnet solutions are built to handle large volumes of material, ensuring high magnetic performance, durability, and reliability.

SGM drum magnets are engineered with proprietary magnetic circuits, optimizing both ferrous attraction strength and separation efficiency. Available in electromagnetic and permanent magnet configurations, they ensure continuous operation in demanding environments

SGM Drum magnetic models

- MDM (Mega Drum Magnet)

Designed for auto shredder applications, offering exceptional ferrous attraction with a larger core section and optimized current density for high-capacity processing.

- PDM (Polishing Drum Magnet): Specialized for reducing copper content in ferrous scrap, featuring anodized aluminum winding for precise control of electrical rotors separation.

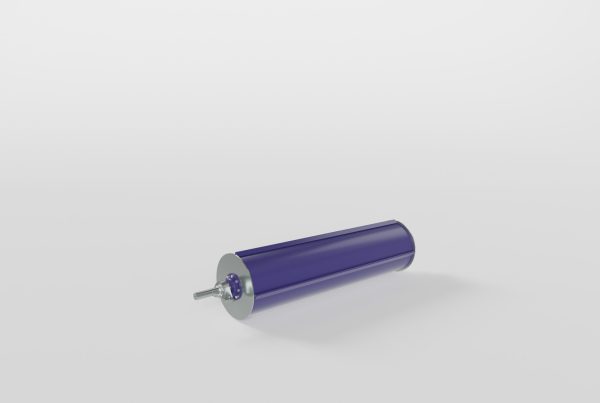

- TMP (Permanent Drum Magnet) → Utilizes a combination of neodymium and ferrite magnets, delivering high magnetic force while ensuring durability in slag, foundries, and WEEE applications.

- TMR (Electro Drum Magnet) → High-performance electromagnetic drum, ideal for auto shredders and heavy industrial applications, featuring axial polarities and low electrical density for optimal heat dissipation

Structure and operation of drum magnetic separators

Drum magnetic separators are composed of two main components:

- The stationary inner part houses the magnetic source, which can be made of either electromagnetic windings or permanent magnet blocks. Depending on the design, two or more polarities may be present, arranged either axially or transversally to optimize separation efficiency.

- The rotating outer shell, made of non-magnetic materials such as manganese or stainless steel, contains axial slats whose number and size vary based on the application.

Unlike pulley magnet separators, which generate a continuous magnetic field around their circumference, drum magnetic separators are magnetically active only on a specific section of the outer shell (typically around 200°). This ensures that ferrous materials are attracted in the active section, while the non-magnetic section allows for the efficient discharge of recovered metals.

Why choose SGM Drum Magnets?

- Custom-engineered magnetic circuits:optimized for maximum separation efficiency.

- Heavy-Duty industrial design: ensuring long-lasting performance in harsh environments.

- High Recovery rates: maximizing the extraction of ferrous materials for increased profitability.

- Multiple Configurations: available in various diameters, widths, and magnetic strengths for different applications.

With decades of experience in ferrous separation technology, SGM provides industry-leading drum magnet solutions.