Eddy Current Separators (ECS) are an essential technology for recovering non-ferrous metals from mixed material streams in recycling and industrial applications. These separators utilize electromagnetic induction to efficiently extract metals such as aluminum, copper, and brass, ensuring high recovery rates and process efficiency.

How the Eddy Current Separator Works

When non-ferrous metals pass through a variable magnetic field, they are exposed to repulsion forces that cause them to be ejected from the material flow. The SGM ECS head drum assembly consists of:

- A rotating magnetic rotor with multiple alternating polarities.

- An external shell that transports the material.

The magnetic rotor spins at a much higher speed than the outer shell, creating a rapidly alternating magnetic field. This induces eddy currents in conductive metals, generating opposing magnetic fields that push them away from the conveyor, separating them from non-metallic materials.

Advanced Concentric Rotor Design

SGM’s Eddy Current Separators feature a concentric rotor design, which allows for:

- Maximum exposure of materials to the magnetic field, enhancing separation efficiency.

- The use of large neodymium permanent magnet blocks, increasing magnetic energy for stronger repulsion forces.

- Gradual and progressive separation, particularly beneficial for fine and ultra-fine materials, unlike eccentric rotors that only allow instantaneous ejection.

- Improved stability and durability, ensuring long-lasting performance in heavy-duty applications.

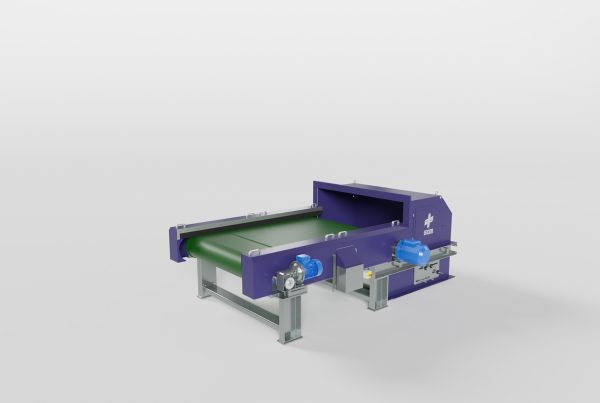

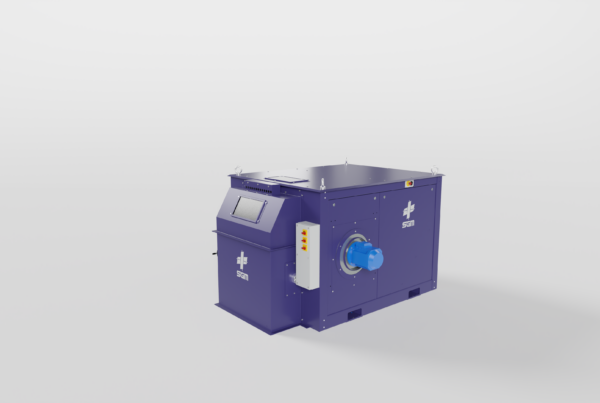

SGM Eddy Current Separator Models

SGM offers a range of ECS models designed for different applications and material types:

- DIS Model → Optimized for municipal solid waste (MSW) and wood waste recycling. Features a concentric rotor for maximum material exposure to the magnetic field, ensuring efficient non-ferrous metal recovery.

- EIS Model → Designed for general waste processing, offering easy maintenance and high performance for separating aluminum, copper, and other non-ferrous metals.

- GVIS Model → Specialized for glass waste recycling, equipped with a reinforced structure to withstand abrasive materials like glass cullet.

- SIS Model → Engineered for large-size materials (20mm-130mm), including auto shredder residue (ASR), municipal solid waste incinerator ash (IBA), and aluminum scrap upgrading.

- VIS Model (High-Frequency ECS) → Designed for ultra-fine material fractions, such as WEEE, ASR, and fine aluminum scrap, featuring variable rotor speeds up to 4,800 rpm for progressive separation.

- BVIS Model → Designed for ultra-fine non-ferrous metal recovery to efficiently separate particles as small as 0.2 mm, maximizing purity in fine material streams.

Why Choose SGM’s ECS?

- High-Efficiency Separation → Optimized rotor design maximizes metal recovery.

- Adaptability to Different Material Streams → Custom configurations for various applications.

- Robust & Durable Build → Designed for continuous operation in demanding environments.

With decades of expertise in separation technology, SGM delivers state-of-the-art solutions to improve recycling efficiency, material purity, and resource recovery, supporting a more sustainable and circular economy.

Typical applications

Different Eddy Current Separator (ECS) designs are essential to meet the specific requirements of various non-ferrous metal separation applications. Factors such as particle size, material composition, and processing environment influence the choice of ECS technology, ensuring optimal recovery rates, purity levels, and operational efficiency. SGM offers a diverse range of ECS models, each tailored to maximize performance in industries such as recycling, waste processing, and metal recovery.