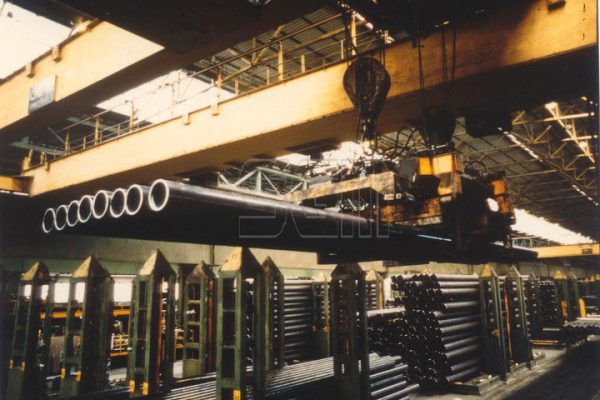

Bundles, Packs, and Layers of Pipes

Handling pipes and tubes presents unique challenges due to variations in diameter, length, and packing density. Whether lifting bundles, packs, or individual tubes, the right magnet system must provide strong magnetic fields to ensure secure handling while minimizing air gaps between the magnet and the load.

SGM Magnetics’ lifting solutions are designed to meet these high demands, featuring customized pole geometries that optimize magnetic penetration. This allows for efficient lifting of densely packed tube bundles, as well as the safe handling of single pipes for precise positioning or commissioning.

SGM electromagnets for this application are compact in design, minimizing overall equipment height without compromising lifting capacity. This space-efficient solution integrates seamlessly into various industrial environments.

Unlike traditional lifting methods that rely on chains, slings, or mechanical clamps, SGM’s electromagnetic systems reduce or eliminate pipe surface damage by ensuring a gentle yet firm grip. This is particularly critical for industries requiring high surface integrity, such as oil and gas, construction, and manufacturing.

Video

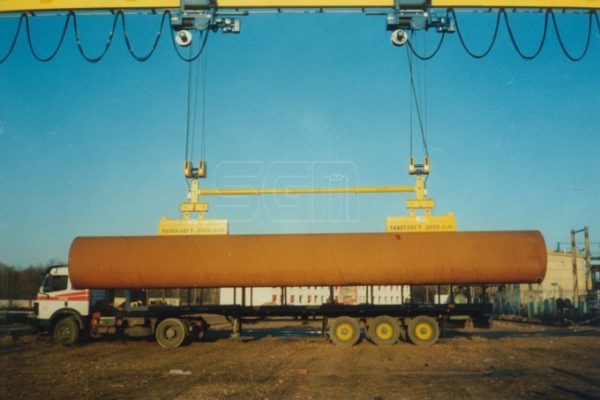

Advanced Spreader Beam Options

SGM offers various spreader beam configurations, adapting to different load requirements:

- Fixed or Motorized Telescopic Beams – Designed for flexibility and efficiency, allowing operators to adjust the lifting system to different bundle sizes.

- Rotating Magnets – Enable precise positioning and orientation of pipes during lifting and stacking.

- Pantograph Functionality – Allows transverse magnet movement, optimizing handling for narrow loads or multiple bundles with a reduced overall width.

Seamless Automation & Control

SGM lifting systems integrate easily into automated material handling processes, featuring advanced electronic controllers that:

- Adjust Magnetic Force – Tailor the lifting power to specific load requirements.

- Monitor Temperature Continuously – Prevent overheating and optimize performance.

- Control Telescopic and Pantograph Movements – Allow for precise, operator-friendly adjustments.

Safety & Operational Efficiency

SGM electromagnets enhance both workplace safety and productivity:

- Single-Operator Control – The entire lifting process is remotely managed from the crane cabin or via wireless control, reducing the need for ground personnel.

- Minimal Maintenance – Built for long-term reliability, with redundant power cables and continuous magnet health monitoring.

- Stable Handling – The magnetic system prevents interaction with surrounding structures, ensuring smooth operations without oscillations or misalignment.

Compliance & Quality Assurance

SGM lifting magnets are designed and manufactured in compliance with European Standard EN 13155, guaranteeing maximum safety and efficiency in pipe handling operations.