Bundles of structural profiles and H-beams

Handling bundles of structural profiles and H-beams presents unique challenges due to their substantial weight, varying lengths (ranging from 6 to 24 meters), and the need for precise placement to prevent damage. Traditional methods using slings or chains often require manual intervention, increasing the risk to personnel and potential damage to materials. These methods can also be time-consuming and may not provide the necessary control for precise positioning.

SGM Magnetics’ expertise in electromagnetic lifting technology provides a comprehensive solution for the safe and efficient handling of structural profiles and H-beams, tailored to meet the specific needs of each operation.

SGM Solutions

Enhanced Safety and Efficiency

- Remote Operation: SGM’s electromagnets allow a single operator to control the lifting process from the crane cabin or a safe distance on the ground, eliminating the need for ground personnel and reducing the risk of accidents.

- Damage Prevention: Unlike slings or chains that can cause dents or scratches, electromagnets provide a non-contact lifting method, preserving the integrity of the structural profiles and H-beams.

Customized Lifting Solutions

- Tailored Magnet Design: SGM specializes in designing magnets that consider the specific load characteristics, including section, length, weight, and temperature, ensuring optimal performance for each application.

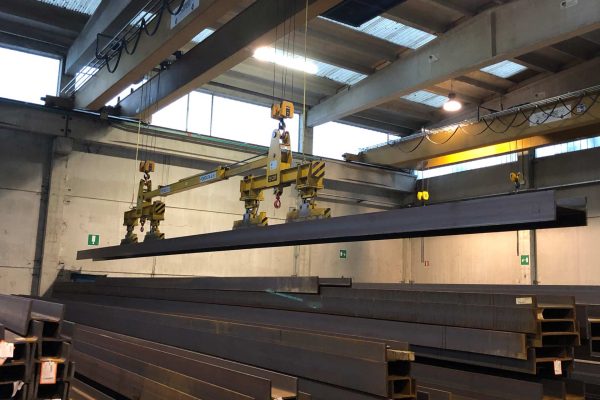

- Motorized Telescopic Spreaders: To accommodate varying load lengths (from 6 to 24 meters), SGM designs and manufactures motorized telescopic spreader beams. These spreaders adjust to the load size, minimizing deflection and ensuring stable handling.

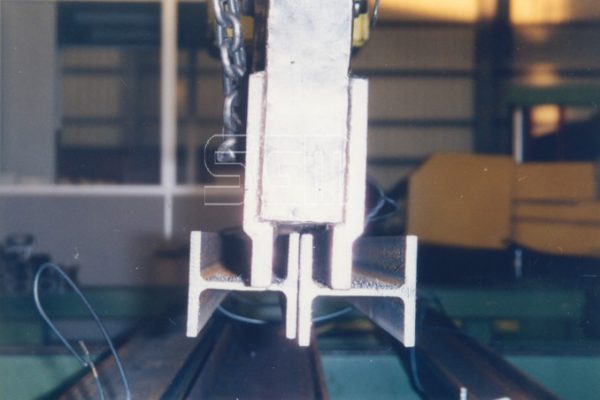

- Movable Polarity Diapason-Type Magnets: These magnets are ideal for handling single profiles lengthwise or multiple profiles crosswise, offering versatility in various operational scenarios.

Operational Advantages

- Increased Productivity: Electromagnetic systems streamline the handling process, significantly reducing the time required for loading and unloading compared to traditional methods.

- Space Optimization: The use of electromagnets eliminates the need for wooden spacers required with chains, allowing for more compact and efficient storage of materials.

-

Cost Savings: By reducing manual labor and minimizing material damage, SGM’s electromagnetic solutions contribute to lower operational costs and improved profitability.

Designed for Industrial Efficiency & Compliance

SGM lifting magnets are designed and manufactured in compliance with European Standard EN 13155, ensuring maximum safety, reliability, and efficiency in structural profile and H-beam handling operations.