The primary component of glass production is silica sand, which melts at 1,700°C and requires 25% more energy compared to recycled glass collected separately. Using recycled glass not only reduces energy consumption but also lowers raw material demand, making glass recycling a key factor in sustainable manufacturing.

Recycling glass is a highly efficient way to save energy during production, as recycled glass melts at lower temperatures than raw materials, reducing energy consumption and emissions.

Glass is one of the few infinitely recyclable packaging materials, allowing for continuous reuse without losing quality. By using recycled glass, industries lower raw material demand, minimize waste, and contribute to a more sustainable production cycle.

Italy ranks second in Europe for glass recycling, processing over 1.8 million tonnes annually, just behind Germany. The sector’s growth has a significant environmental impact, preventing 189 million tonnes of raw material extraction and diverting 138 million tonnes of waste from landfills, reinforcing the importance of efficient separation and recycling technologies.

Glass separation and recycling

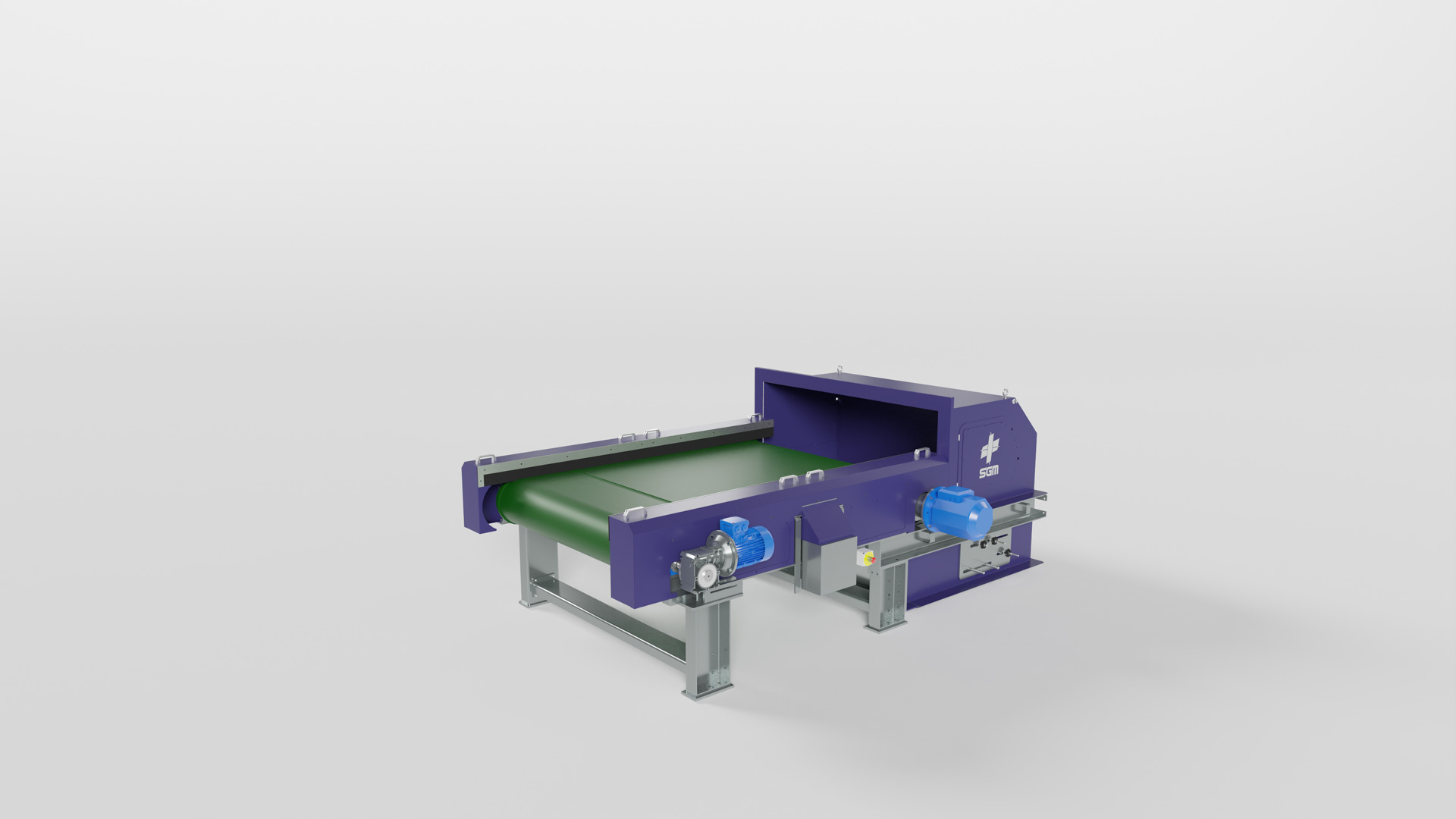

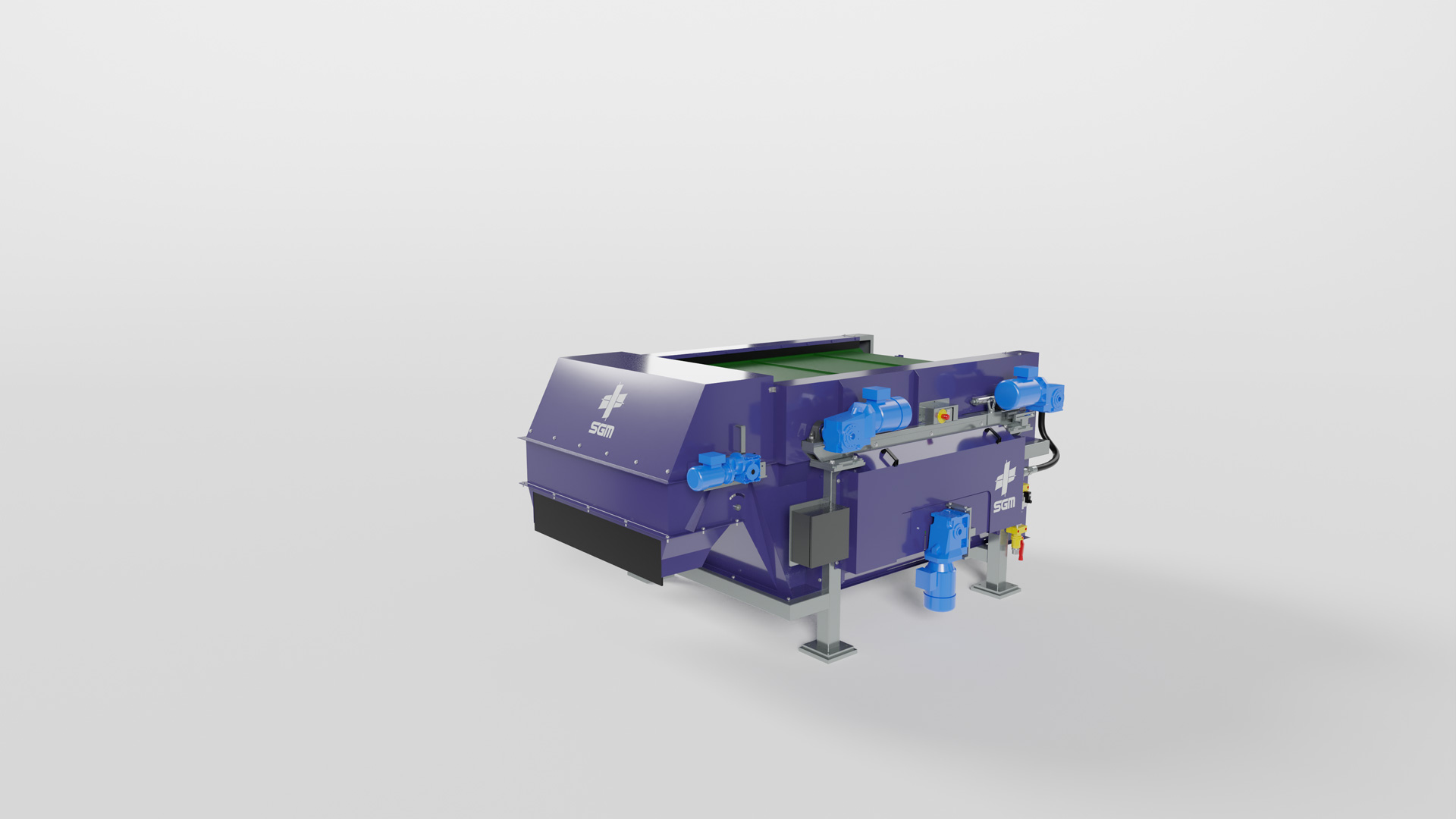

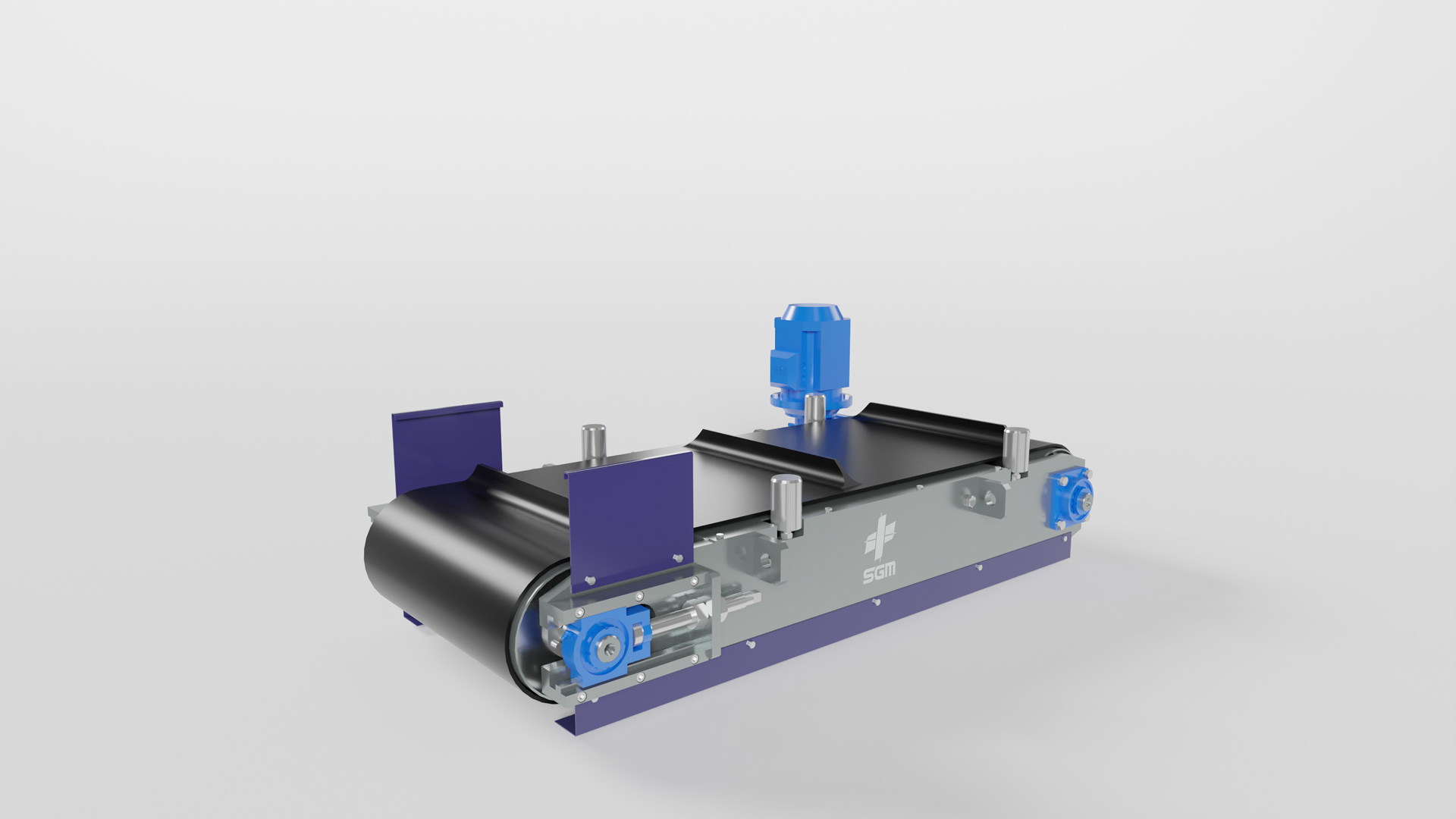

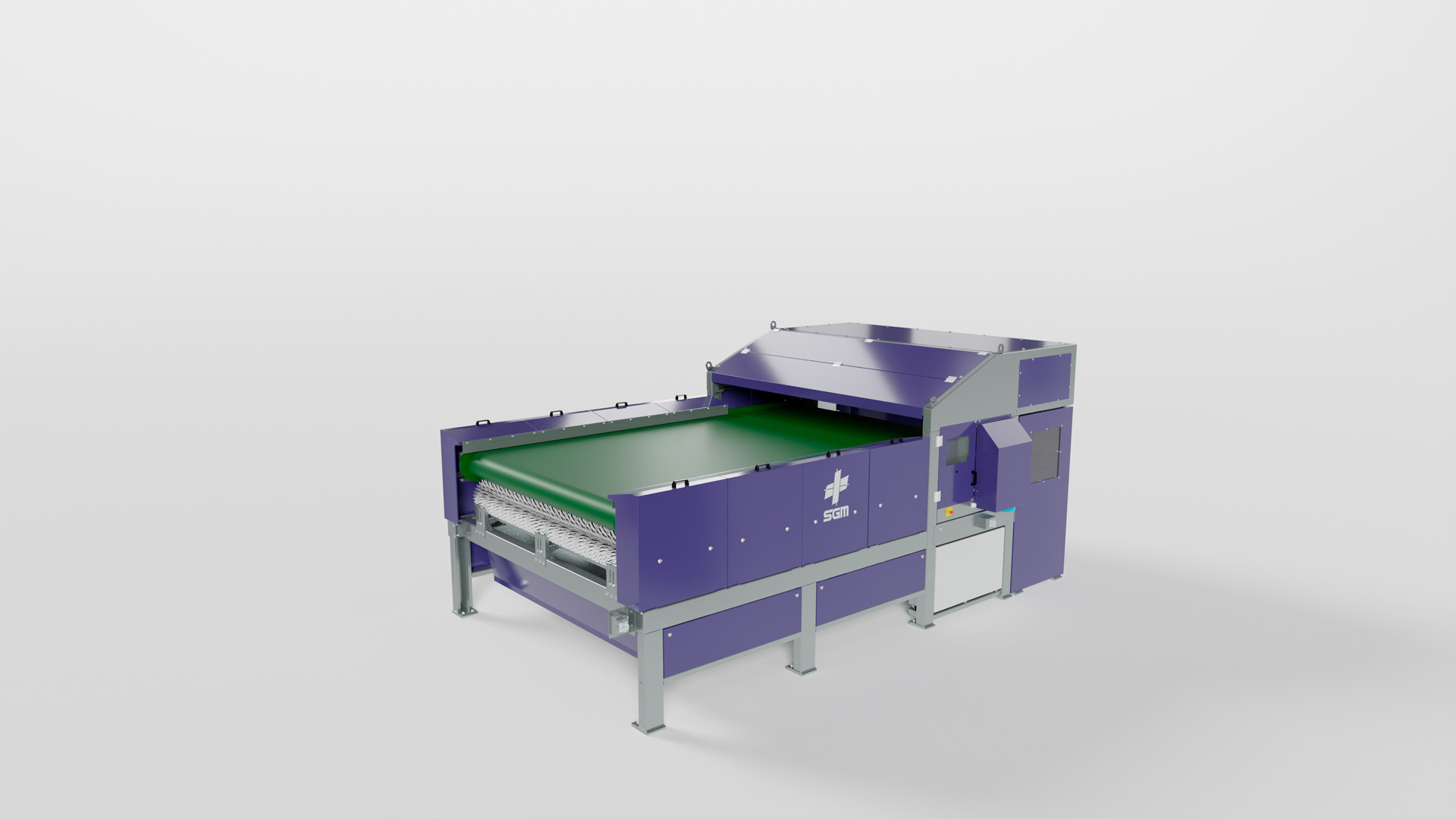

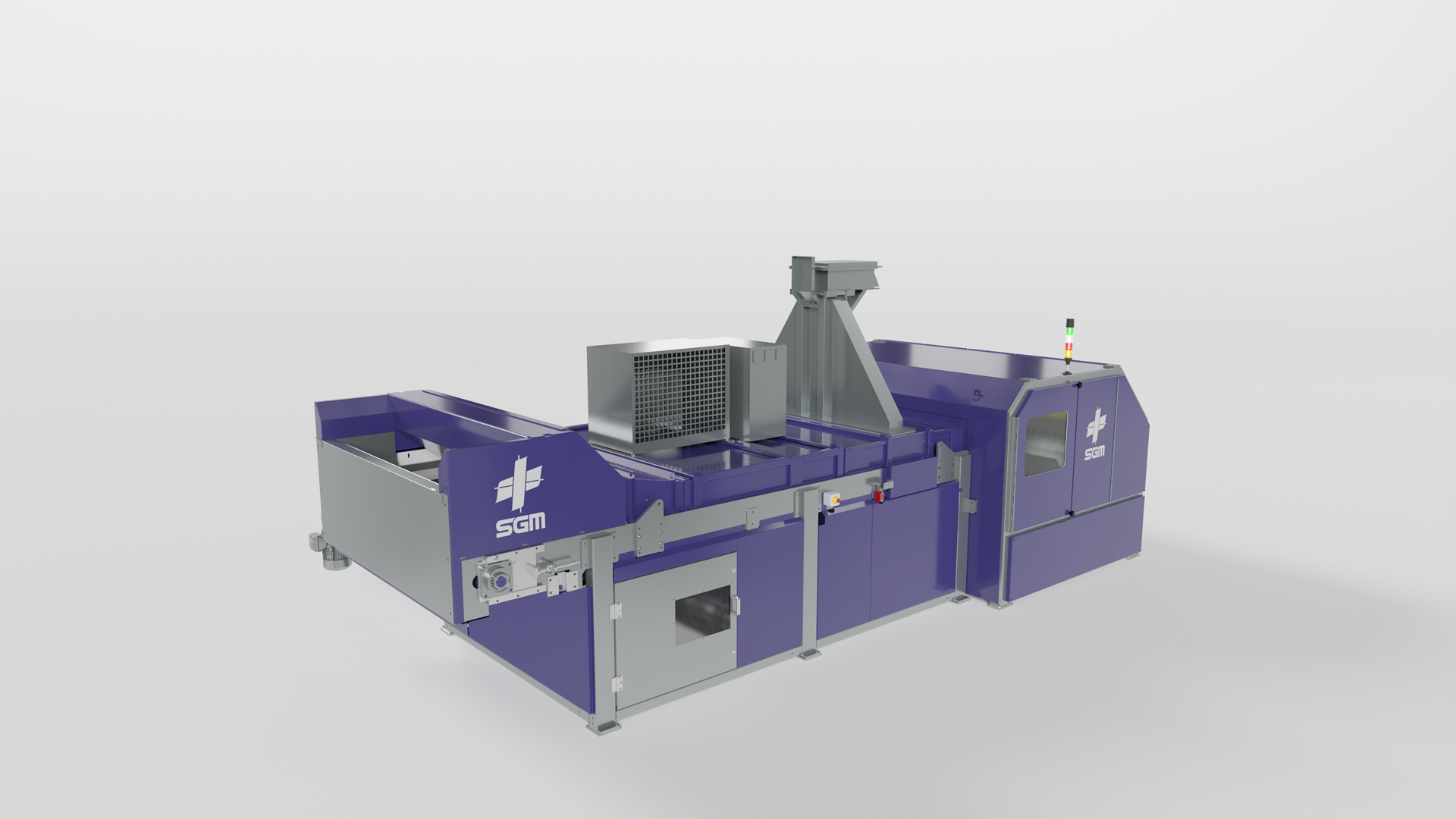

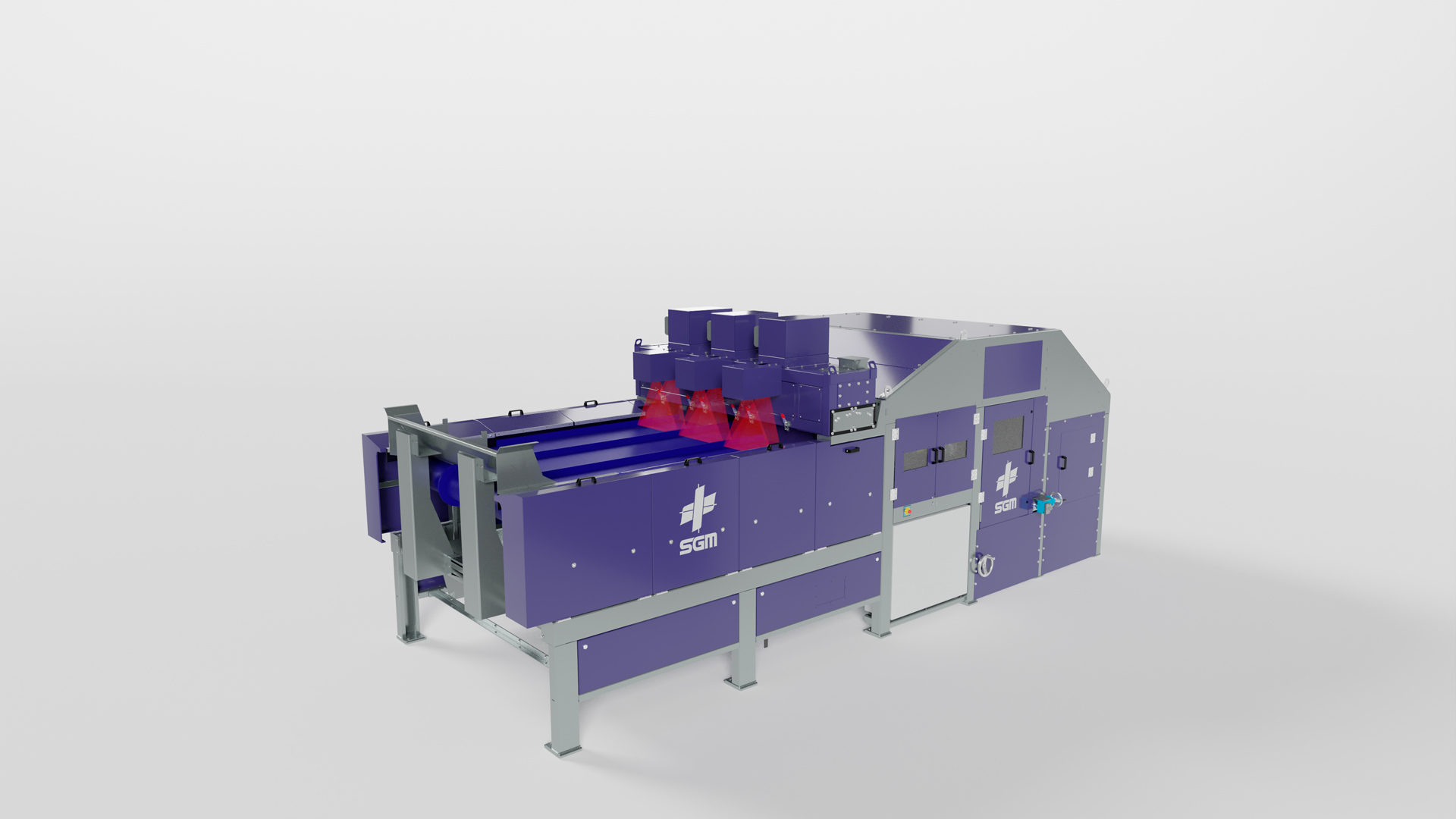

Based on the experience of working with glass recyclers in countries like France and Italy where glass cullet is characterized by a large quantity of wine bottles with lead sleeves on their necks, SGM has developed a complete range of specific separators for removing both ferrous and nonferrous metal contaminants including free lead, leaded glass, heat resistant glass, other non-ferrous metals and steel reinforced glass.

SGM has extended its experience to many other international glass cullet recyclers and is a technology leader in this field with a complete range of magnetic ferrous separators, eddy current separators, induction sensor based sorters, colour sorters and X-ray sorters.

Customers that trust us