At SGM Magnetics, we provide cutting-edge technologies for the pre-concentration and purification of iron and manganese ores, combining dry and wet separation solutions to optimize efficiency, reduce operational costs, and maximize recovery.

Our Solutions for Iron Ore Processing

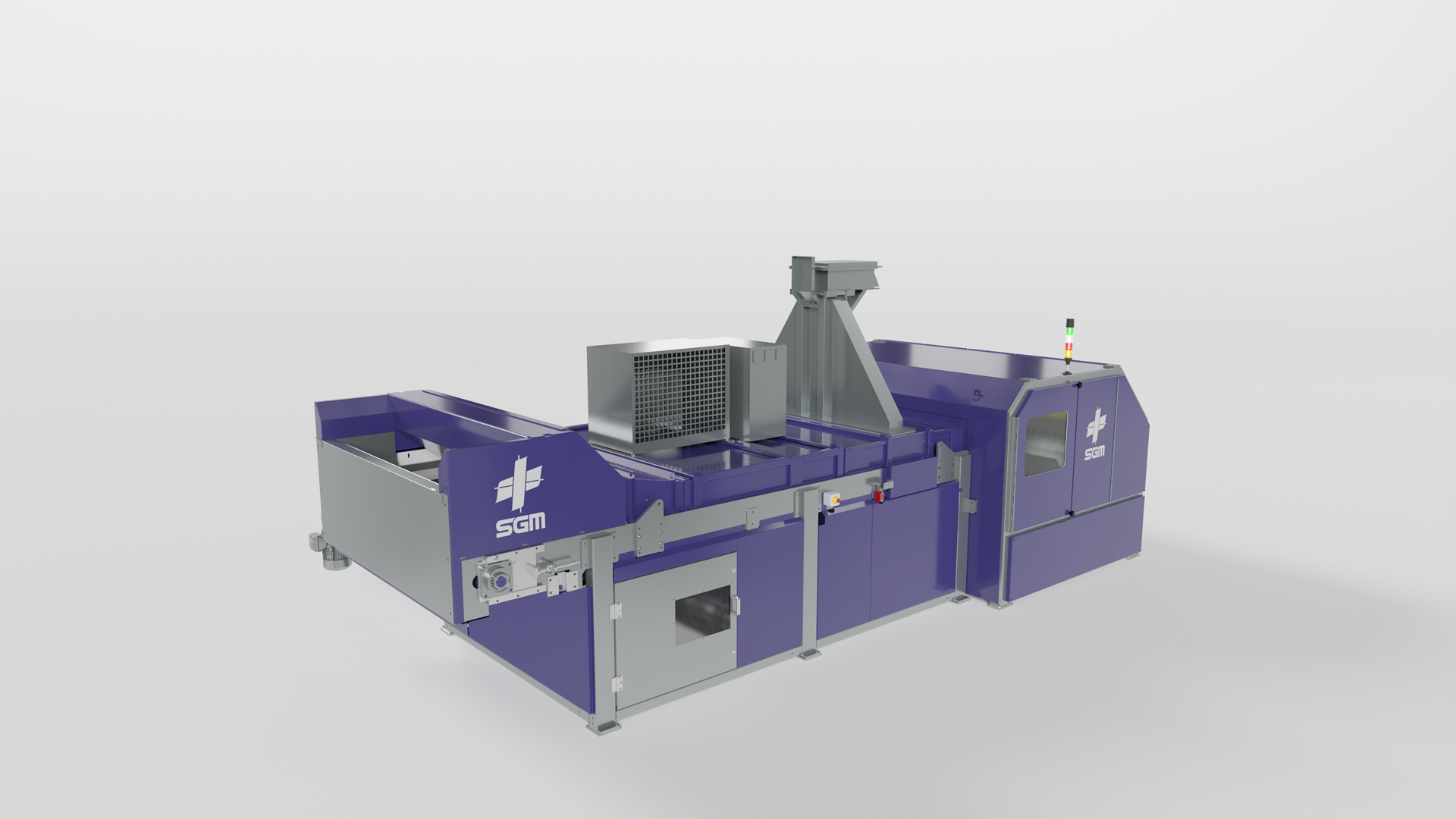

SGM X-Ray Transmission (XRT) Sorter

Our XRT sorting technology is an ideal dry processing solution for the pre-concentration of iron and manganese ores. By analyzing the atomic density of the material, it efficiently separates valuable ore from waste rock, reducing water and energy consumption while increasing overall throughput.

SGM MIMS – Medium Intensity Magnetic Separator

The SGM MIMS wet drum separator represents a revolutionary step in wet separation, bridging the gap between traditional LIMS (Low Intensity Magnetic Separators) and WHIMS (Wet High Intensity Magnetic Separators).

Key benefits:

Unmatched recovery and purity – The proprietary magnetic circuit ensures a homogeneous high-gradient magnetic field across the entire separation arc, improving the capture of weakly magnetic iron ore particles.

Boosts WHIMS efficiency – When positioned before a WHIMS, it pre-concentrates the feed, significantly enhancing productivity and reducing clogging risks.

High processing capacity – Available in diameters up to 1,050 mm (41 inches) and widths of 3 meters (10 feet), it can handle over 150 cubic meters per hour and up to 120 tons per hour, depending on the application.

Flexible operation – Works in concurrent or counter-current configurations, with or without a custom-designed tank for optimized separation.

With SGM Magnetics’ XRT and MIMS technologies, mining operations can achieve higher efficiency, better resource utilization, and improved sustainability in iron ore processing.