A complete natural resource, this noble material sees every part of itself employed in surprisingly versatile ways. Wood is a recyclable material par excellence, which plays a fundamental role in the fight against climate change because of its ability to absorb carbon dioxide. The recycling of wood at the end of life allows then to “freeze” the stored carbon dioxide, thus avoiding the release into the atmosphere of millions of tons of CO2 compared to other uses, such as waste to energy.

Every year millions of tonnes of wood are disposed of for all sorts of reasons. Only about 15% of waste wood is recycled across the world and that 9 billion m³ of underbark (inner layer of tree bark) is removed from global forests annually, almost half (49%) of this underbark is used as wood fuel – the rest is for industrial roundwood (used by wood processors).

Urban waste wood is increasingly recycled to be used for the production of wood-based panels or other applications, for which the removal of metal contaminants is crucial.

Wood Recycling

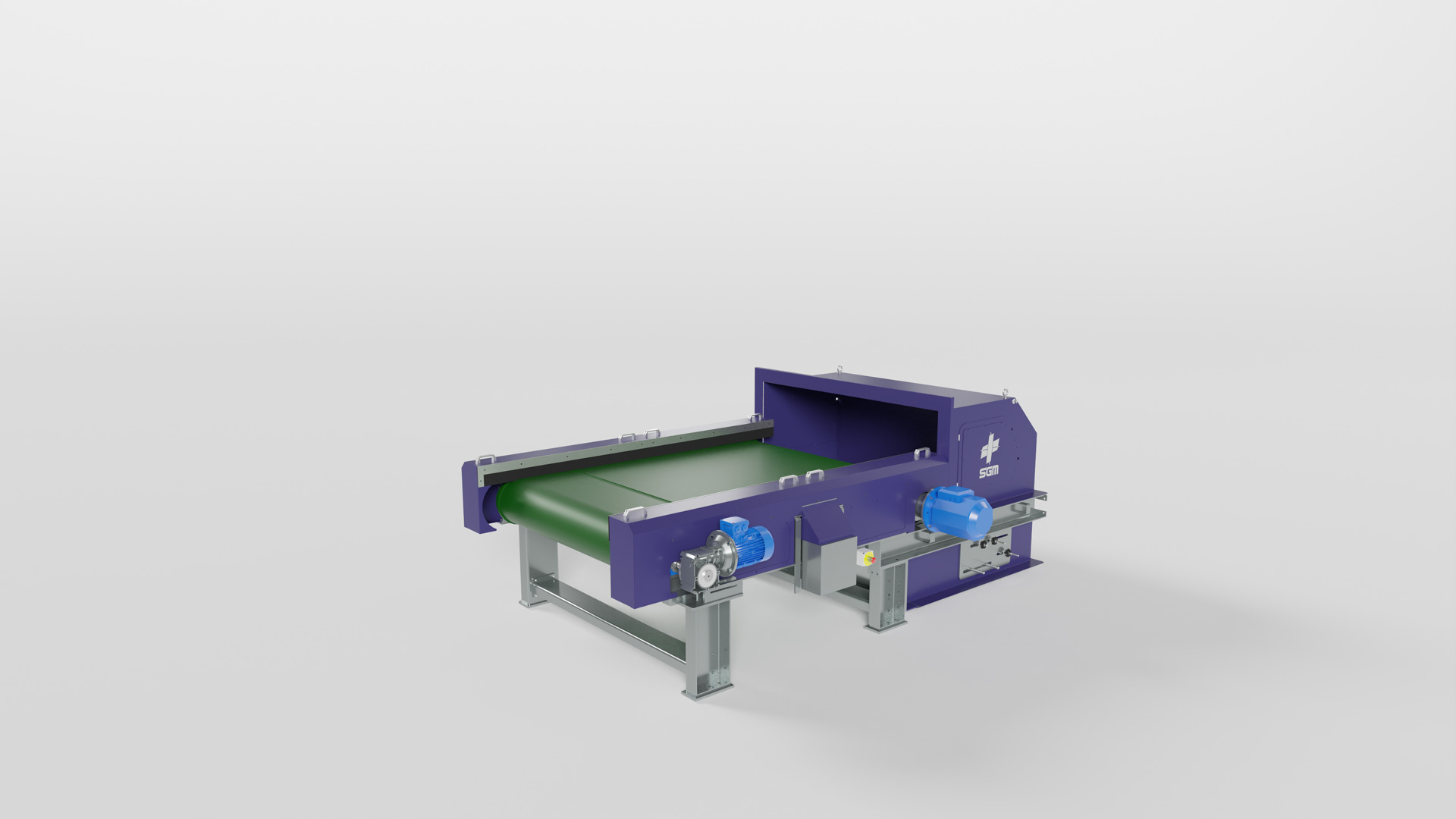

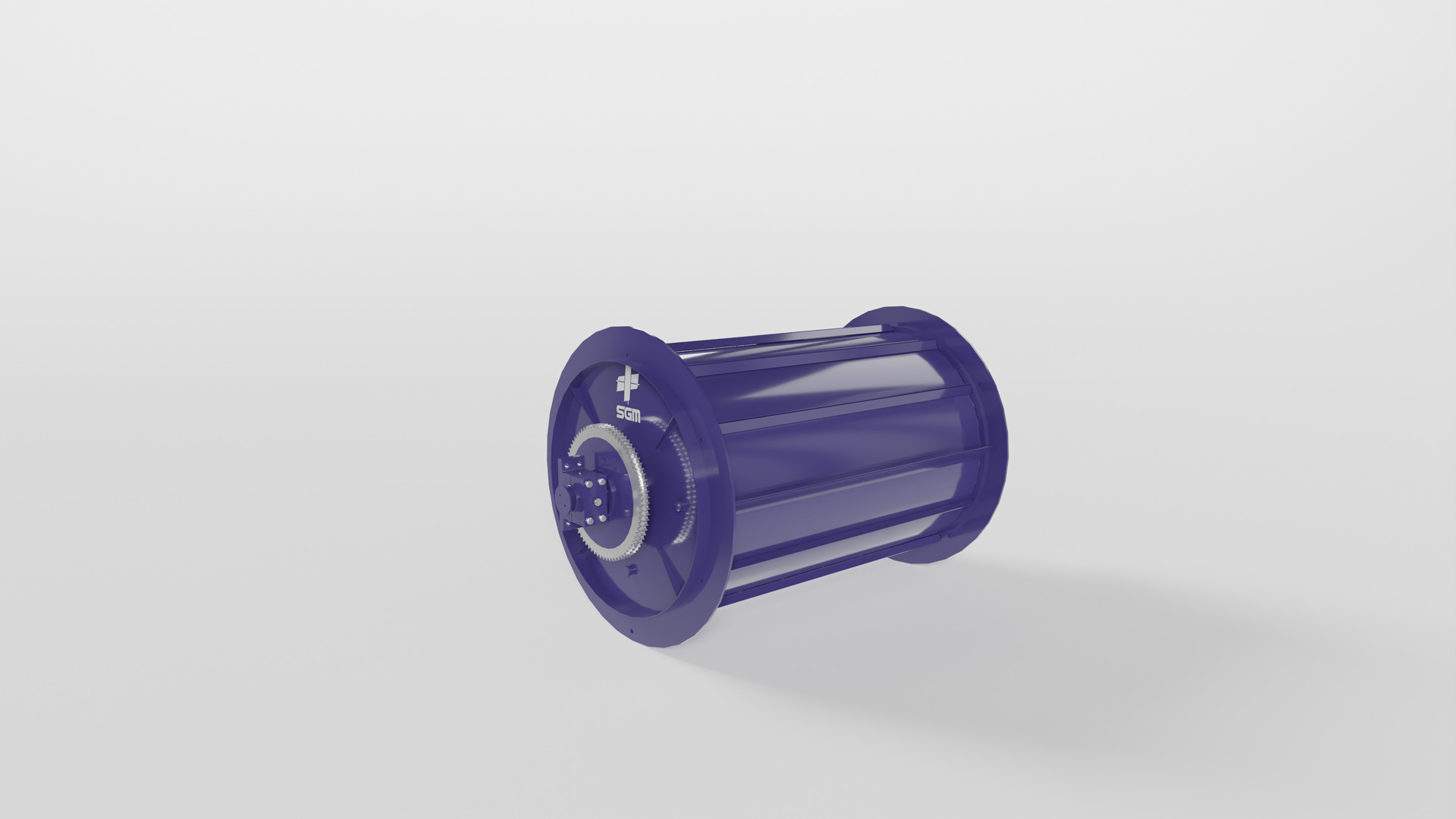

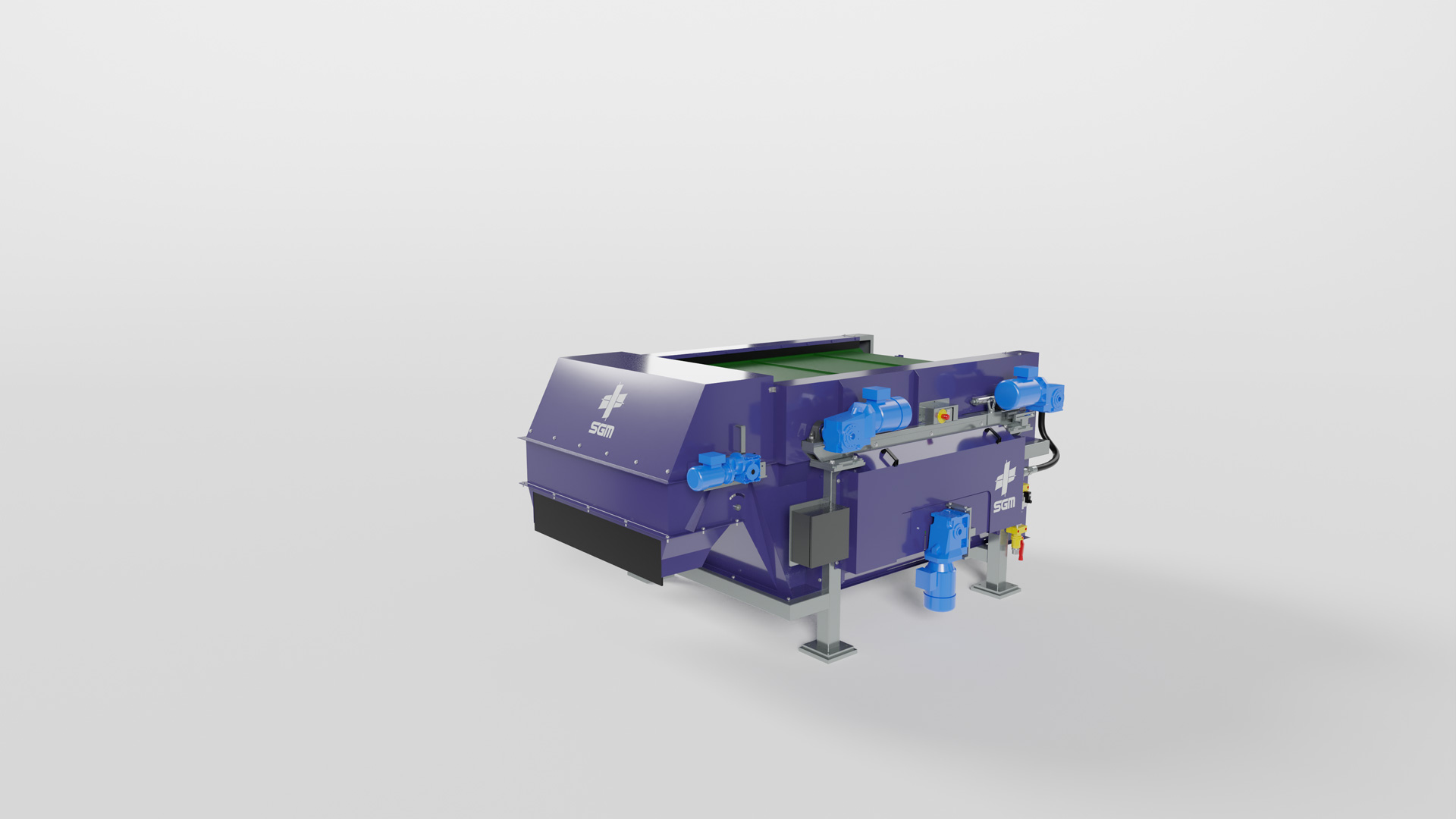

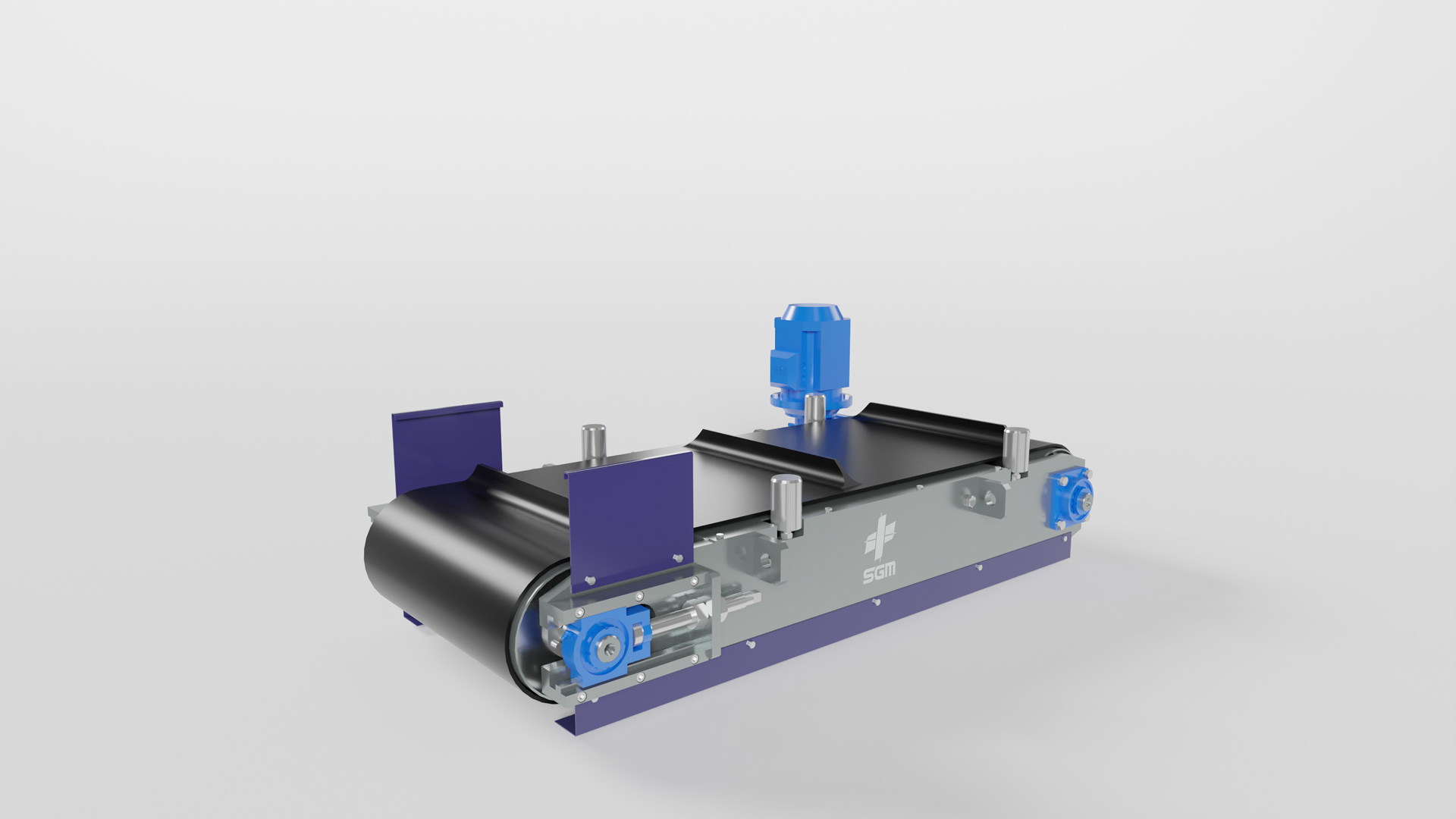

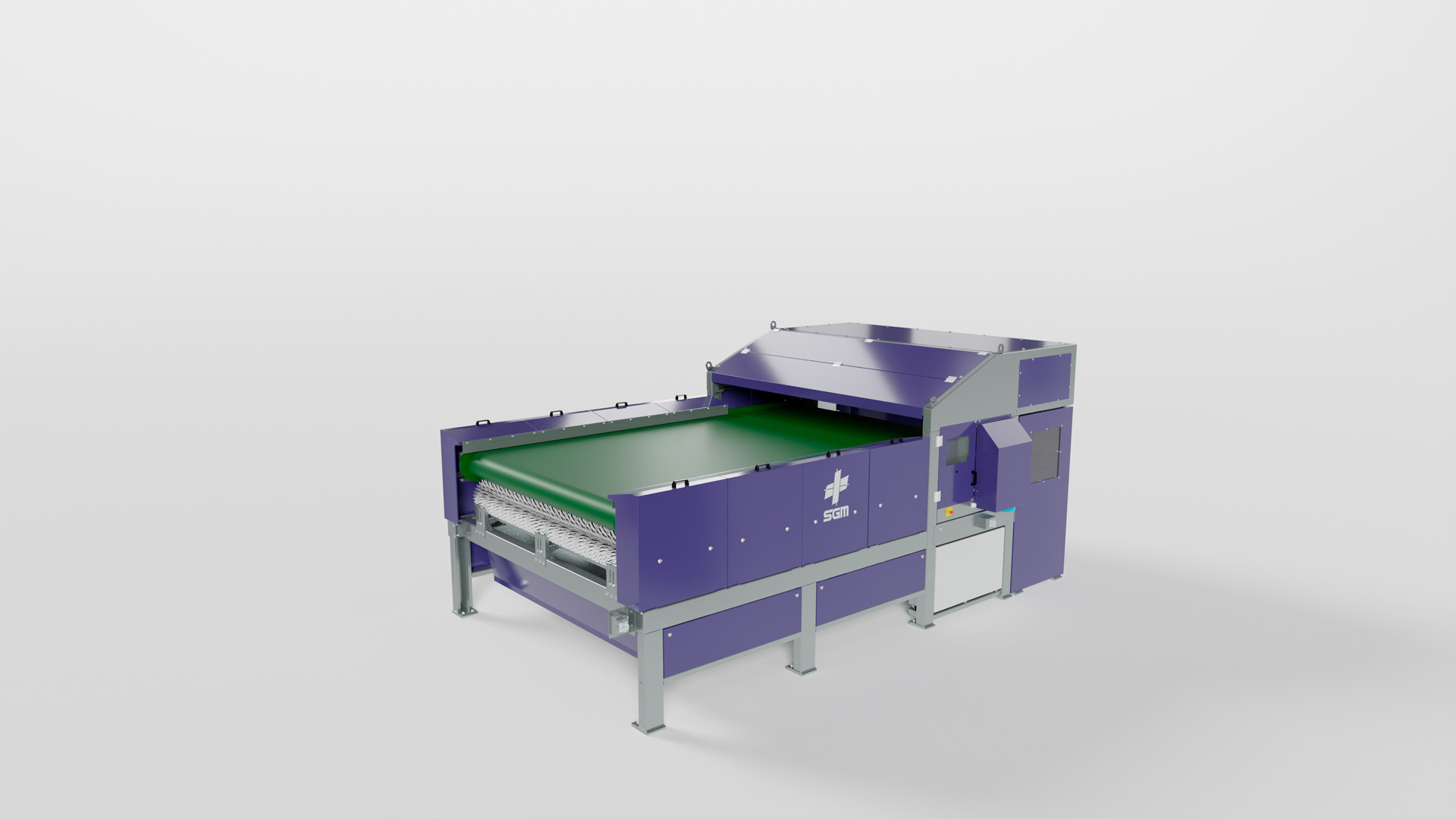

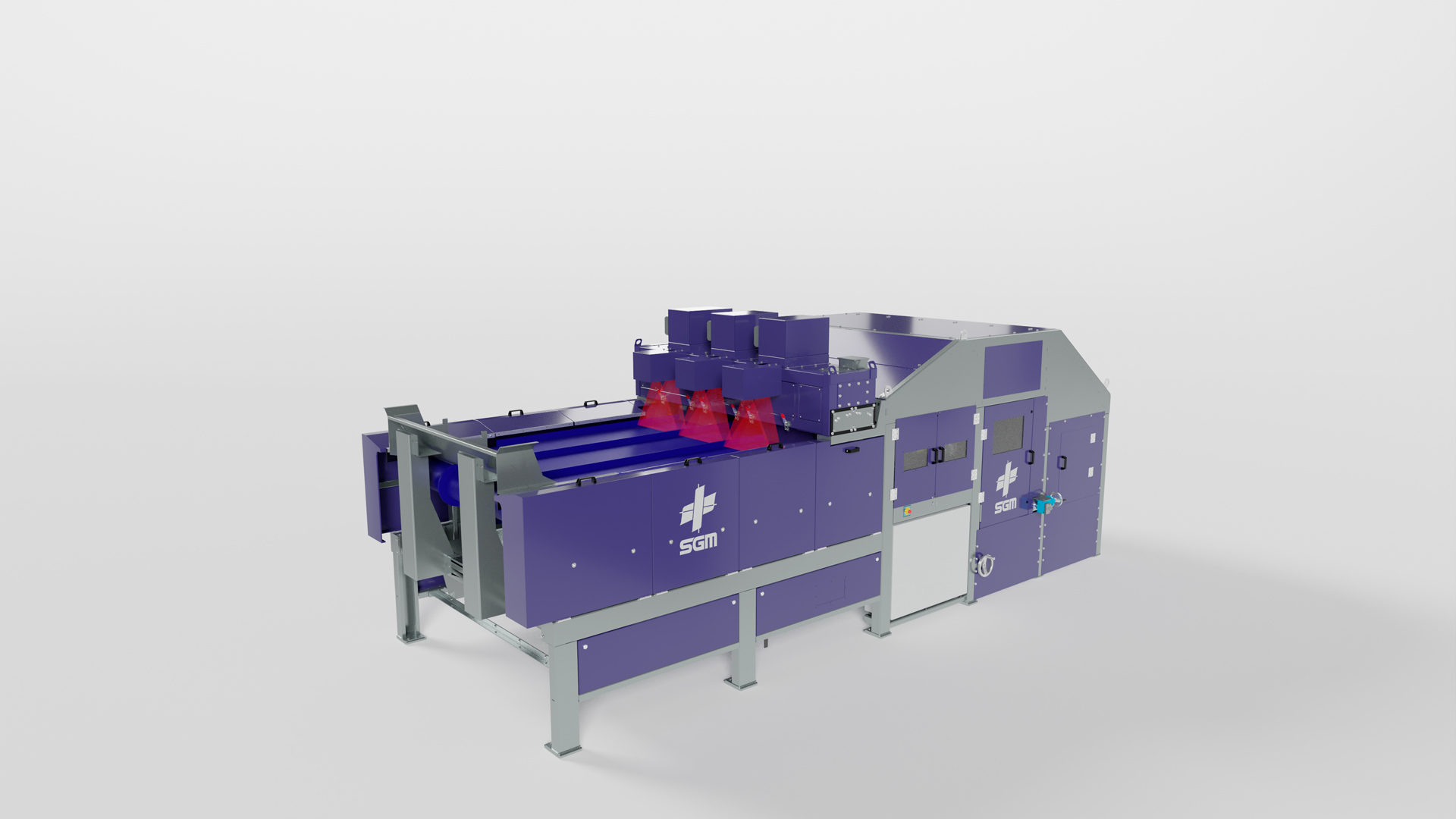

Drawing from extensive experience working with the Italian wood-based panel industry, SGM has developed a complete range of specialized separators designed to remove ferrous and non-ferrous metal contaminants at various stages of the urban waste wood recycling process.

Our solutions ensure efficient metal removal whether the wood waste is still raw or has been further processed into chips and flakes before reaching the panel press. By providing high-performance separation technologies, SGM helps improve material purity, process efficiency, and product quality, supporting a more sustainable and reliable wood recycling industry.

SGM has expanded its expertise to urban wood waste recyclers worldwide, becoming a technology leader in this sector.

SGM offers a comprehensive range of separation solutions, including:

- Magnetic ferrous separators: Removal of ferrous contaminants.

- Eddy current separators: Recovery of non-ferrous metals.

- Induction sensor-based sorters: Detection and separation of metal contaminants.

- Air gravity tables: Separation of light and heavy fractions.

Additionally, SGM separators can be designed to meet ATEX requirements, ensuring safe operation in explosive or hazardous environments where dust and flammable materials are present.

Customers that trust us